Powder bed metal 3D printing is a super cool technology that allows us to make metal stuff. It is a different and special way of creating objects than what we normally use. In this article, we will explain how does powder bed metal custom 3d printing work as well as why it is so cool. So come on in and check out this wicked process

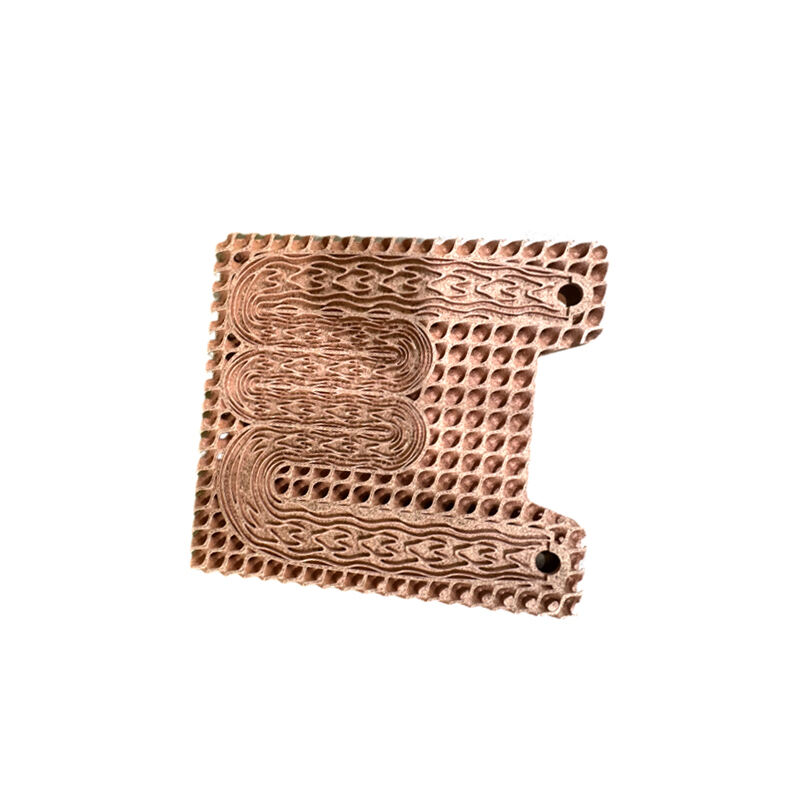

Powder bed metal 3D printing technology (DMLM / SLM / DMP) builds 3D objects using small metal powders, layer by layer. Let's say we are building a tower using blocks, one at a time. It begins with a fine, dust-thin coat of metal powder, distributed over a flat plane. Next, a special machine melts the powder with a high-powered laser in the areas that will make up the part. When the laser hits the powder, it converts the powder into a solid layer. This process is repeated over and over again, with more layers being placed on top until the whole object is constructed. It is similar to playing with Legos only this time instead of plastic blocks, we play with metal powder!

The last date you can use the data: October 2023. They always try to innovate new ways of this technology. They have built new customizable 3d prints equipment that melts the metal powder much more quickly and accurately. These advancements allow us to produce more sophisticated, intricate metal objects than ever before. These advancements have created exciting new possibilities in various industries such as aerospace, aviation, automotive, automobiles, and even healthcare, medical equipment that you can see around or a medical device that you can use.

To have a powder bed metal 3D printing for manufacturing means many great benefits. Because it is able to produce such complex and intricate designs, this is one of the strongest benefits, as traditional manufacturing methods could not create such designs. It allows us to design components that fit together very well and function efficiently. Apart from that, this technology minimizes waste as it uses only the metal powder required to create the object. Not only does this save materials, but it speeds up production, saving time and money for companies. Plus it’s super awesome to see a metal object being formed layer by layer right in front of your eyes!

Common Materials in Powder Bed Metal 3d printing customization Stainless steel, titanium, and aluminum stainless are just a few of the materials. These metals are strong and durable, which makes them ideal for the manufacture of all kinds of items, from airplane parts to medical implants, which are placed inside people’s bodies. These materials all have unique properties, meaning they are all special in their own way. The ideal material for the job must be picked to ensure that the end product is safe and effective.

Indeed, the horizon of powder bed metal 3D printing technology is bright and abundant! Pulesheng Technology continues to explore now materials and processes that will revolutionize the way we produce things. In a few years, who knows how many astonishing metal elements we've been going to be observed to be being made by this new-fangled innovation. What this indicates is that the advancing personalised technologies will allow us to have brilliant products that we feel that we can better use them in our life.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

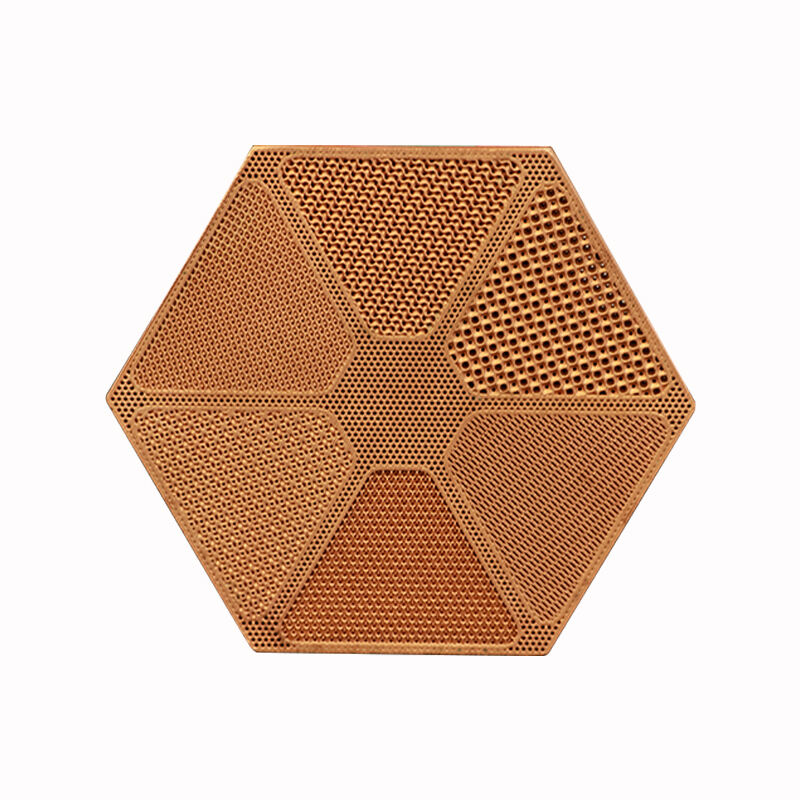

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.