When I say "binder" you might think about a notebook you keep your papers in or some special kind of glue that helps things stick together. But what most don’t know is that metal 3d printing filament binders are also something that is of great importance in the exciting world of 3D printing. Pulesheng Technology uses a special solvent – binder jetting binder material to create wonder

The next question is, what is binder jetting binder material? Put in layman terms, This is an innovative technique where a liquid binder is used to bind the small particles of material. These are basically metal powders or sand. Our Methods When SLS printing, a high-powered laser is fired and computer controlled. It’s like blocks, but MUCH cooler!

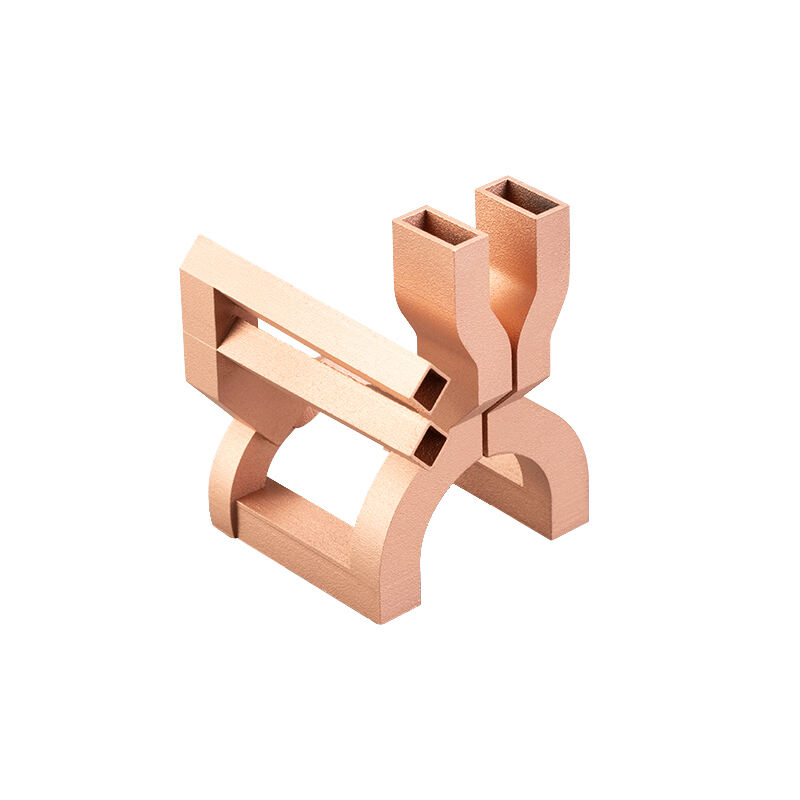

The great thing about binder jetting is its efficiency. This means the binder is used only in the areas where it is truly needed, resulting in minimal waste. It’s better for our planet, too, because we don’t throw materials away. It also saves money which is critical for businesses. Binder jet technology also lets us produce things with extremely thin walls and complex geometry — features that might be difficult to achieve with other processes. This print 3d on demand allows us to create better looking and functioning things

Now, let’s discuss how binder material aids in this process. The binder material is a liquid that binds the small particles of material together. It typically consists of water and some binding agent, a special ingredient. Binder is then jetted, layer by layer, from a printhead. This is akin to spraying ink on paper like an inkjet printer.

The binder’s job is primarily to hold the individual particles together until the complete object is finished. Once we print the object, we place it in the oven. This online 3d printing service removes additional binder, allowing the particles to tightly bind together to for a solid object. This grid is vital to ensuring that the object is robust and long-lasting.

As with any technology, scientists and researchers are continuously pushing the envelope to produce better binder materials for 3D printing. Over the past several years, they have made significant advances in the development of new and improved binder materials. They 3dprinting have focused on areas like making binders that can be used with a much broader range of materials, including ceramics and metals. This provides new avenues for creating objects with distinctive properties and attributes.

Moreover, binder jetting is quicker and cheaper than conventional manufacturing processes. This is excellent for producing prototypes, but binder jetting can even be used by factories for small or large quantities. We at Pulesheng Technology are continually exploring new applications for binder jetting and binder materials. We feel this tech can revolutionize the manufacturing industry and pave the way towards a cleaner and more efficient future for all.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.