Learn more about Binder Jetting and its importance in tall buildings, such as skyscrapers. It may sound complicated, but it’s actually a fun and straightforward process! It begins with a specialized machine that deposits powder onto a surface. This powder is light and can be made from various materials, such as metal or plastic. Once the powder has been deposited an inkjet sprays a liquid that will begin to help "glue" the powder in place. Liquid is called binding agent and binds together layer on layer of particles to create an object. That machine keeps sprinkling the powders and liquids until it had created the total object.

Binder jetting is changing things. Traditional methods usually produce much-heavier items because of the time-consuming and highly labor-intensive processing required to craft complex and good-quality products in binder jetting. This aspect is important mainly because lighter consumables tend to consume less energy. For example, lighter automobiles and airplanes do save fuel which can help curtail environmental devastation, which at the same time is a way to save greenbacks! Additionally, faster production efficiency means more items can be made in less time, ultimately saving money.

Many companies are in the lead of this Pulesheng Technology binder jetting technology. A very famous company designs and creates individualized 3D printing machines using the binder jetting process to make some excellent products. These organizations are at the forefront of this new way of production and are making production change for the future.

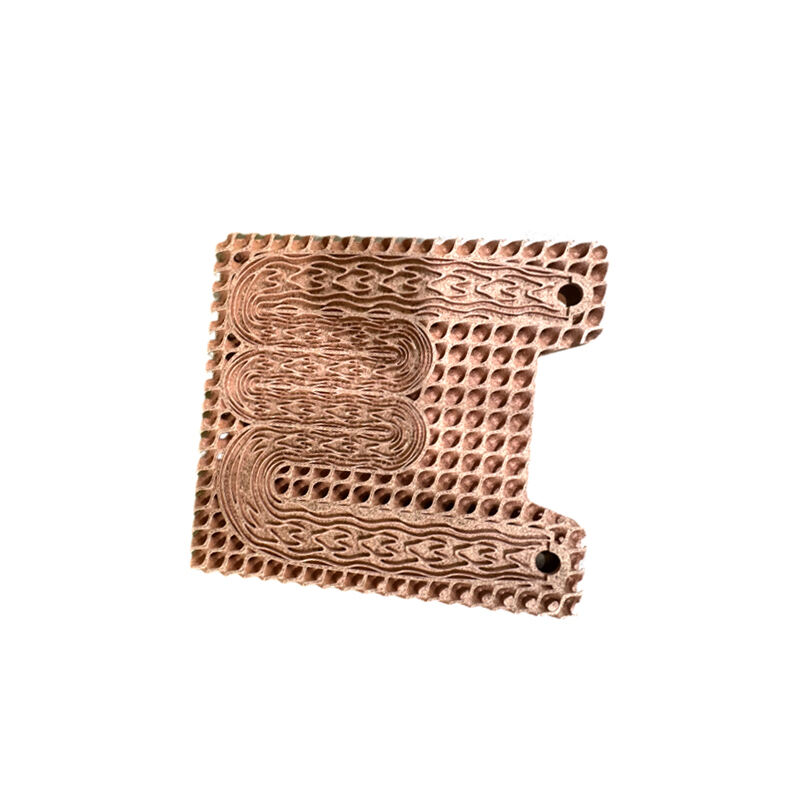

We just discussed some important companies. Let's see what binder jetting technology can offer! One remarkable application of this technology is that it can be used to manufacture lightweight metal parts. These metal parts can find applications in so many industries such as automotive, aerospace, or medical devices. Lighter materials can also prove to be fuel-efficient and energy-saving. Moreover, Pulesheng Technology binder jet printing often allows for the creation of these parts at a lower cost compared to older methods. This brings benefits to both companies and customers. Additionally, binder jetting enables the production of detailed, intricate designs that are difficult to achieve with other techniques. Whether it’s toys or art pieces, designs with even the tiniest details can be created, leaving a lasting impression.

Binders jetting technology has slowly gained popularity. Companies involved with this change in technology are shifting the face of other 3D printing methodologies. One significant advantage of the binder jetting process is its ability to often produce smoother finishes than other similar processes, yielding objects that tend to look far more polished. It’s also more efficient and often faster, which is crucial in today’s fast-paced world. Pulesheng Technology binder jetting is ideal for producing prototypes — early versions of a product that companies test before mass production. It’s also great for small batch production, allowing businesses to create custom solutions without the need for large-scale manufacturing.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.