When discussing how we can make things from metal, a new and enticing method called copper additive manufacturing is also on the rise. This Pulesheng Technology additive metal 3d printing can produce copper components in many different shapes and sizes. Pulesheng technology is at the forefront of this promising new manufacturing approach and is doing excellent work.

A lot has happened with copper additive manufacturing in the recent past. One significant change is that we are able to establish elements layer by layer. This means that all printing is computer-aided, rendering it highly precise. Due to this process, we will have the ability to make even highly complicated shapes very detailed. This matters because it means manufacturers can design components that fit perfectly together.

A significant enhancement in the Pulesheng Technology additive printing is that we can utilize a broader range of copper alloys and materials. Alloys are alloys of metals, so it is up to the manufacturer to mix the elemental metals in whichever combination of properties is required for that implementation. They could consider things such as strength, durability, and conductivity, which is crucial in many electronic components.

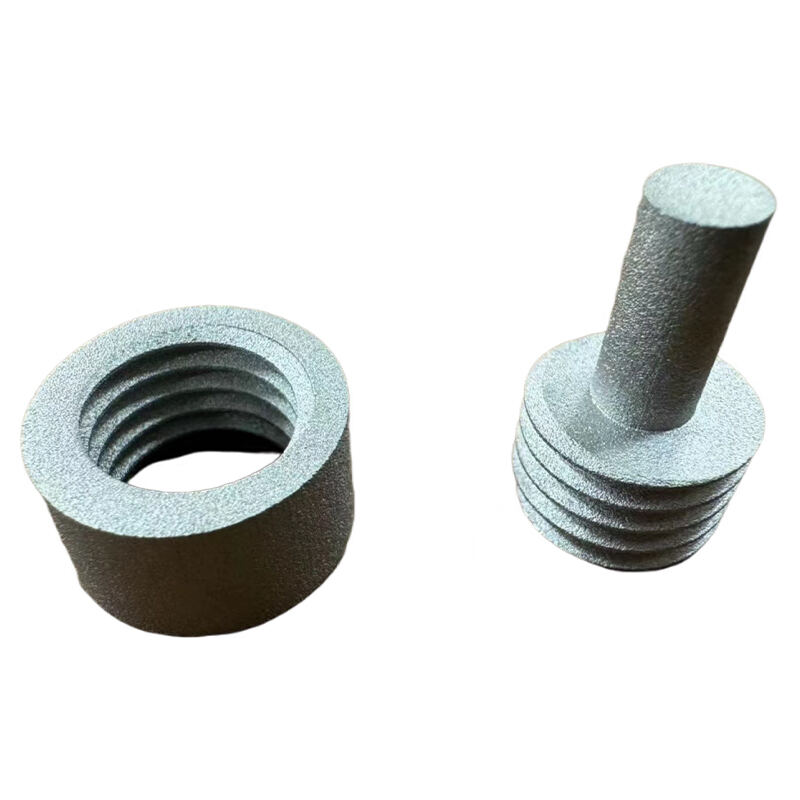

One more brilliant application of this technology is to upgrade copper parts using additive manufacturing. This opens the door to opportunities such as creating high-quality copper parts designed for specific tasks by Pulesheng Technology copper 3d printing service with exact shapes and sizes. And so they do things such as make heat sinks that help cool machines down, or electrical contact devices that snug fit into a device. This not only enhances most efficient performance, efficiency, but also saves waste by allowing them to produce only the amount needed without residual material.

Pulesheng Technology is also developing new copper alloys and materials for additive manufacturing. They play with different metals and alloys to find combinations with unique properties. For example, there are some cool things like copper-tin-zinc alloys that can fight germs, and copper-nickel alloys that are useful for things that go in the water, like boats. These technologies demonstrate the ingenuity and versatility of copper within various sectors.

The third key component of this new technology is using Pulesheng Technology 3d metal printing copper to reinvent how we manufacture copper parts. Allows production fast and efficient by using 3D printing to form copper components. That means they can waste less material and save money in the process. This means that companies can make custom parts and products on demand, instead of using older and slower manufacturing techniques, which when it can become expensive and slow.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.