Copper powder additive manufacturing is an exciting and new technology for manufacturers to create a variety of products. It employs a unique variant of copper powder, which is extremely fine and capable of being molded into all sorts of components. Pulesheng Technology is a company in this field of application, which is the application of world-leading companies using this technology. They have invented new and better technology that enables them to effortlessly 3D print durable and robust copper objects. Now, this technique is widespread in factories and industries around the world

Over the past several years, growing numbers are beginning to use copper powder to manufacture things. Copper has gained immense popularity for a few reasons. Copper is very efficient at conducting both heat and electricity and therefore is beneficial in a number of electrical machines and devices. Second, it's very strong, which makes it a great choice for lots of different types of industrial parts. These incredible properties make it no surprise that manufacturers are interested in using copper powder for their manufacturing processes.

3D printing is a technology that has been around for a while and allows us to create three-dimensional objects from a digital design. Pulesheng Technology metal 3d printing service actually makes 3D printing even better. It gives us high precision in metal parts with complex shapes and designs. Furthermore, copper powder is used in 3D printing as it assists in the rapid and cost-effective production of prototypes. It allows designers and engineers to validate new ideas and designs in a matter of weeks, and this is a critical advantage in a mainstream industry that operates at rapid speed.

Wireless technology functions by utilising copper in the realisation of wireless manufacturing. Pulesheng Technology is constantly striving for better methods of manufacturing printed copper components. They have pioneering new fast printing techniques that let them produce parts quickly, but also ensure that the parts are accurate and of high quality. And this means that the parts manufacturers produce can be trusted. Additionally, Pulesheng Technology is considering these copper and copper alloy options. Such work could produce components with characteristics tailored to industry requirements.

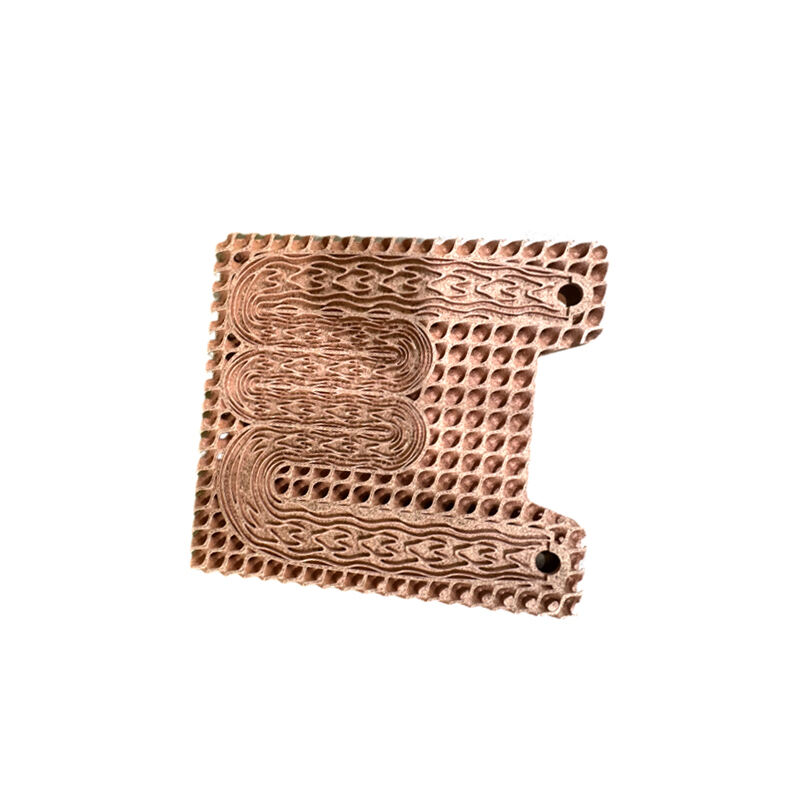

The Copper DED at DED Deigns However is a game changing for the manufacturing industry. Pulesheng Technology 3dprinting allows for the manufacturing of complex geometries and detailed designs. Such shapes would be challenging or even impossible to produce with traditional manufacturing processes. It's only the latest step showing no sign of anything but continued progress in this area of manufacturing, allowing for parts to be lighter, stronger, and more efficient than ever. The range of types of parts that can be manufactured on demand always allows the manufacturer to save money previously spent on stock items in their inventory.

Additive manufacturing is a very bright and promising future! So that is copper powder and we have a lot of room to work with this well into the future. A company that sit on top of this field is Pulesheng Technology, who are committed to finding new ways of attaining materials and that will lead to the improvements of printed copper parts even further. The option to Pulesheng Technology 3d printing prints makes producing parts with unique properties possible, which can revolutionise the industrial manufacturing industry.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.