More and more businesses are turning to custom metal 3D printing, which is an exciting and innovative way to manufacture a diverse range of metal structures and components. Known as Direct Laser Deposition, this special process employs a unique printer whose operation involves successively adding layers of metal to grow objects. It’s similar to building blocks, except instead of blocks we stack metal! This online 3d printing service technology is transforming how things are made across multiple industries globally. But, companies like Pulesheng Technology are assisting with this exciting new technology by providing customers all over the world with metal 3D printing services so whatever parts you need custom may be made easier

Custom metal 3D printing is really simplifying the process for the world to make all sorts of things. Before its with data up to October 2023, creating products and items was a lengthy and costly process. It lit a path through factories that had to use up a lot of resources and different machines to make even a simple item. However, we can do it much faster and more effectively with custom metal 3D printing now. This new technology is particularly excellent for complex shapes that are difficult to manufacture with older methods. They can dream up products that turn into a concrete product rather than only an idea in a designer's head.

Custom metal 3D printing goes through an iterative improvement process. The machines used for the process today are getting quicker, accurate and very inexpensive businesses. This metal 3d printing filament allows more companies to implement this technology to build their products. We are also developing new materials, which help us produce stronger and tougher objects than ever. At Pulesheng Technology, we continue to keep abreast with the most recent developments in custom metal 3D printing. They strive to give all the best services and products to their customers.

Custom Metal 3D Printing Benefits The greatest advantage is that it enables us to generate one-of-a-kind and extraordinary things. This binder jetting is particularly useful for model making or small scale production. Custom Metal 3D Printing 3D printing service is the best solution when a person needs a unique part for the machine they designed or a unique design for their project. Moreover, custom metal 3D printed parts produce less waste than traditional manufacturing methods. That’s because we can produce precisely what we need, and we don’t have surplus materials left over. And this saves not only money, but also the environment.

Custom metal 3D printing is very effective at solving a great many design problems. We can build intricate shapes and designs that would be extremely difficult to achieve with traditional manufacturing processes with this awesome technology. These 3d print on demand unique designs are applicable in a wide range of applications, from aircraft to medical hardware. As a company committed to assisting their clients in this process, Puleseng Technology strives to deliver the best design solutions. They pay attention to customer needs and collaborate to build the best products they can.

Custom metal 3D printing is full of possibilities in the world of art and building design. It enables to designers and architects to create complex and intricate models that 3d printing suppliers would have been impossible otherwise. For example, sculptures can be made by the artists, and wonderful buildings can be made by the architects. From bold sculptures to trendy building facades, custom metal 3D printing can make those creative dreams a reality. Pulesheng Technology looks forward to seeing how this technology ends up shaping and changing the world art and architecture for years to come.

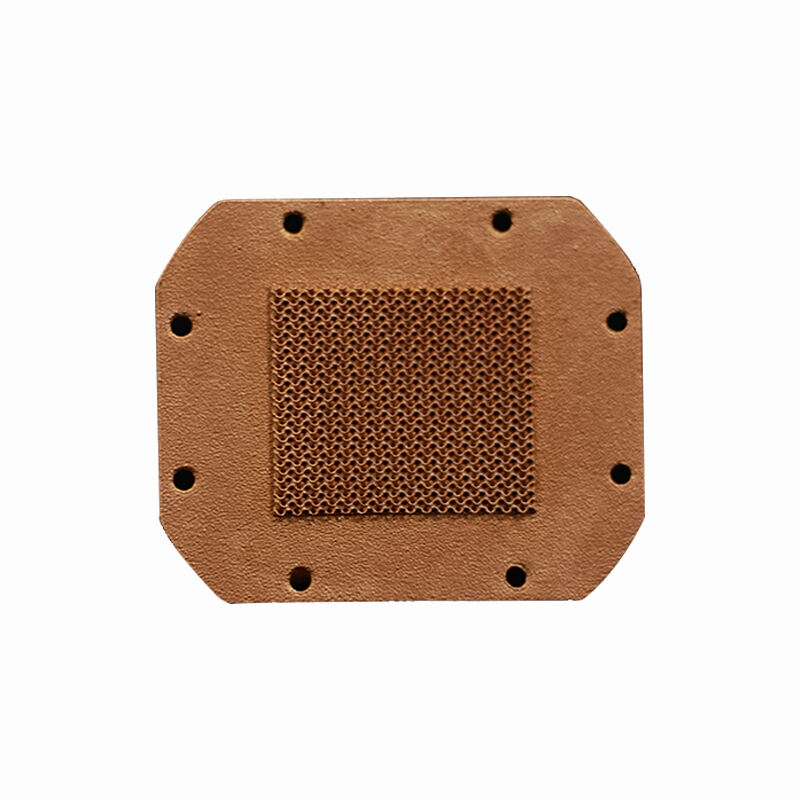

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.