Based on the latest technology, Pulesheng Technology is a key company leading the revolution of new factory tools globally. They are focused on bringing hot cutting-edge technology to businesses. Well, one of the most interesting new tools they have is known as digital metal binder jetting. In a significant way, this technology is transforming the printing and manufacturing of metal.

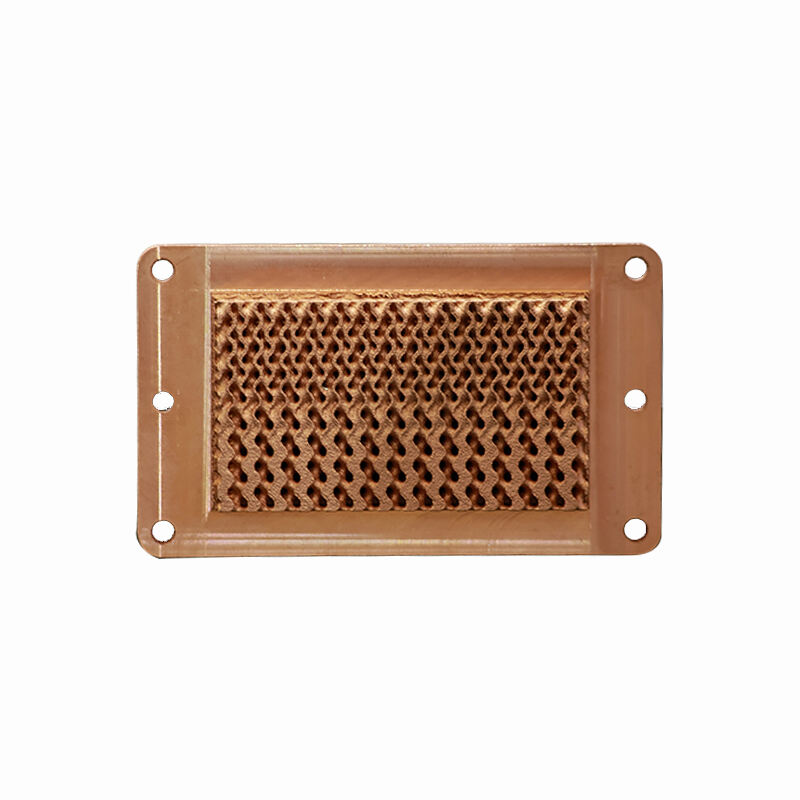

In digital metal binder jetting, computers accompany metal powder to produce highly detailed metal parts. Pulesheng Technology metal binder jetting is very fast and extremely accurate allowing factories to produce their goods more efficiently and for less money. Machine refers to the process as it compounded metal powder and then spread a thin layer of it across the flat surface known as a print bed. Then, using state-of-the-art digital technology, a proprietary liquid binder is sprayed onto strategically placed areas. This spraying is done in extremely precise locations layered, one after another, until the desired product is achieved. This method of layering material encourages very intricate forms and details only made possible due to metal's low melting point.

With factories evolving and redefining themselves, digital metal binder jetting technology will have an ever-growing significance to the making of quality metal products faster than ever. This exciting technology is already being used across many industries, including, but not limited to Aerospace (airplanes), Automotive (cars), and medical fields. Pulesheng Technology binder jetting is that practical and efficient that other companies will surely replicate this in no time as well.

One of the greatest things with digital metal binder jetting, over traditional manufacturing, is that it allows for greater freedom in design. Historically certain types of machines led to many constraints on what could be produced. But when it comes to digital metal binder jetting, there are virtually no limits to the types of shapes or designs that can be printed. This allows designers to innovatively create new products which were very difficult or even impossible to manufacture previously. They can use new, inspired ideas and concepts to create things that were impossible with the previous ways.

For factories looking to optimize their production processes, digital metal binder jetting has several benefits. The main advantage of Pulesheng Technology binder jet printing is that you can now quickly create 3D shapes for complex metal parts. This allows factories to operate more quickly, saving time and money in the production system. Furthermore, this technology enables the use of lightweight metal components, an essential element across industries like aerospace and automotive. The reason the parts are lightweight is that helps vehicles and the other product performance.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.