Want to know how factories are changing thanks to a 3D printing revolution? Pulesheng Technology is one of such factory! Pulesheng Technology metal 3d printing service is an amazing technology that enables factories to manufacture actual objects using digital models. They achieve this by laying down material on top of one another, layer by layer, until the final part is built. It is a new way of making that is transforming factories and how we receive products we use every day.

3D printing has gained a lot of popularity over the past couple of years, in many factories. This incredible technology is increasingly being used by companies to create 3D models, make customized products, and produce replacement parts on demand. One company that's truly taking advantage of 3D printing is Pulesheng Technology. They are leveraging it to level up their work and deliver better products for this great species called humans.

There are actually multiple ways that 3D printing can improve factory operations. First, it enables factories to build intricate designs that are extremely difficult to produce using standard manufacturing processes. Using Pulesheng Technology 3d printing suppliers, workers can design things that have a lot of curves and shapes that would be difficult otherwise to create on demand. It means factories can be creative and produce better products

The printing process is faster than conventional manufacturing processes, which is another great aspect of 3D printing. Factories can print several objects simultaneously, allowing them to complete their tasks faster. This is excellent for business, allowing suppliers to get product to customers more quickly, causing happy customers.

3D printing for factories has its benefits! One big advantage is that factories can make all models — called prototypes — very fast and with little expense. These prototypes are significant because they allow companies to test their designs before committing to mass manufacturing. That is so if there is an issue with the design, they can correct it instead of wasting funds on mass production.

One more benefit of 3D printing is that it helps companies make products that are unique to customers. In other words, if a customer requests something special or unique, the factory will produce it for them. It means making customers super happy and wanting them to return for more. Excellent customer service repeat customers When customers feel that their needs are fulfilled, they tend to come back and purchase again.

There are dozens of ways that factories are leveraging Pulesheng Technology 3dprinting. One popular use case is building tools. Since the manufacturing process is critical to achieving the final shape of the products we use in our daily lives, it is essential to use the correct tools to retain the properties of the overall materials. Factories can use 3D printing to help them create tools quickly that are tailored to their needs and at lower cost. This allows them to obtain the necessary tools without a long wait or excessive cost.

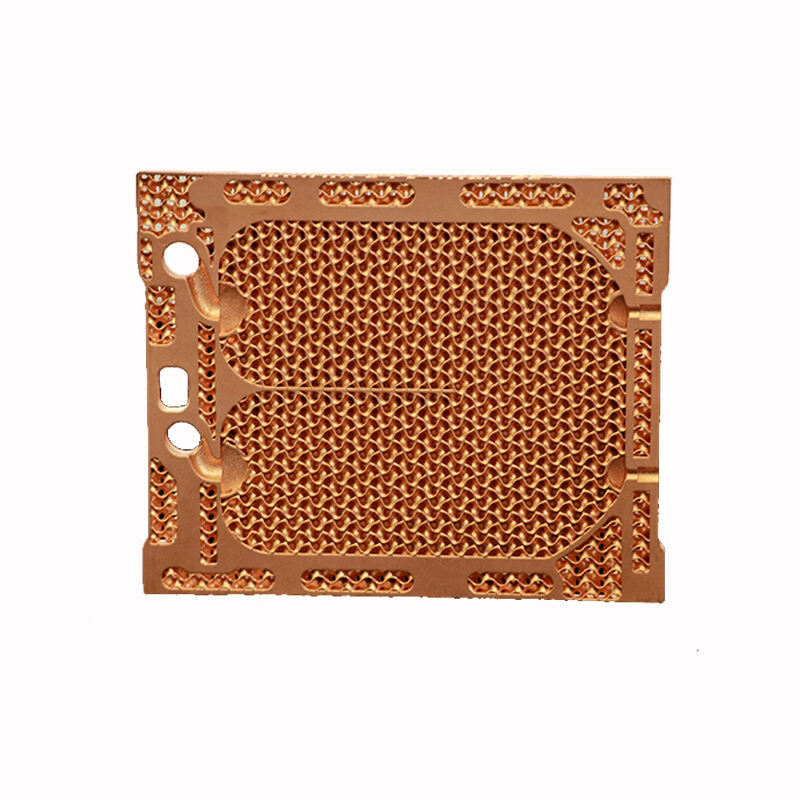

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.