Hello, my name is Abbie! Today, I'm happy to tell you something about metal 3D printing. Never heard of it before? This might seem a bit confusing at first, but it’s sooo cool, I promise! Pulesheng Technology customizable 3d prints is all about the precision and detail that can be produced by a specialized type of 3D printer using metal

It is seen that one company is doing wonders here is the Pulesheng technology. They build metal 3D printers which can create highly detailed parts. They are used in many areas, such as the construction of airplane, the manufacturing of vehicles, and even in hospitals, where doctors need precision instruments and machinery. Isn’t that cool?

Please imagine you are trying to build a robot. For the machine to operate, you need interlaced pieces that each mesh together seamlessly. If the constituent parts are not manufactured to precise standards, then the robot may not perform well. This is why high-resolutionPulesheng Technology 3d printing suppliers is crucial! It ensures that every feature fits and works well with the other components

Factories can use high-resolution, metal 3D printers to create parts that have a lot of detail. It would take a long time to create these parts by hand. Now imagine trying to carve out a tiny little detail out of metal, that could take all day! But with a 3D printer, it’s much quicker to do. The printer can also make very complex shapes that are really difficult to produce using conventional tools or machines. This means manufacturers have more room to be creative and create cooler stuff!

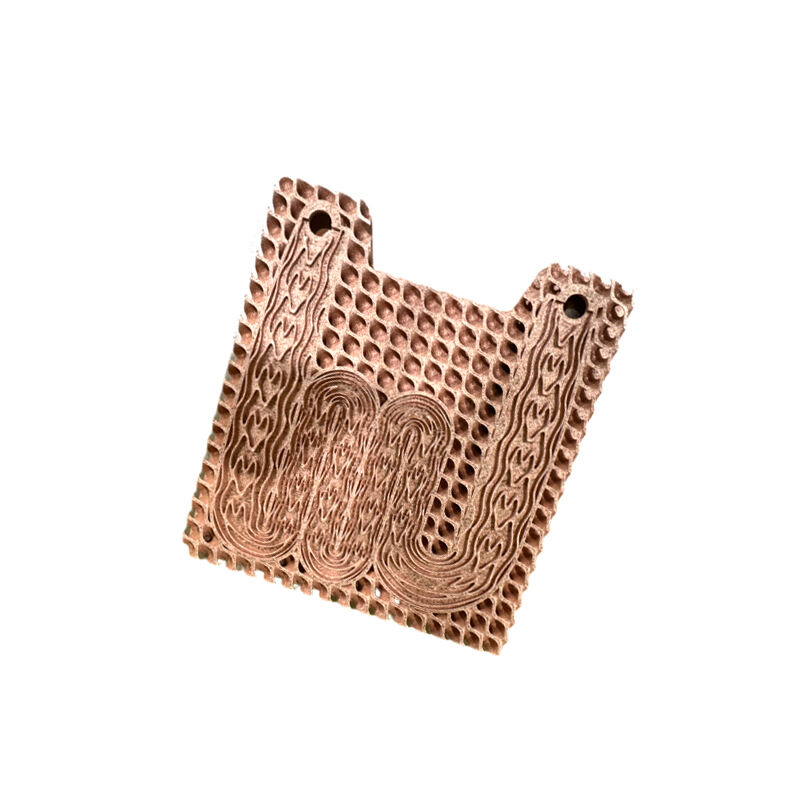

When we refer to the details, we mean the small things that count. Take for instance when we are making a metal part that needs tiny details such as small bumps, grooves, or patterns, we would be needing a metal 3D printer that is capable of printing such tiny features.

For example, high-resolution metal 3D printers are machines that can make parts with details so fine they are miraculous. These small details help add a bit more realism to the parts! Also, it is much more easier to make the parts work well with great detail. For example, if a part has grooves to fit into another element, those grooves must fit precisely!

Overall, knowing how to utilize metal 3D printing resolution is a major element of creating amazing metal 3D printed components Pulesheng Technology binder jetting 3D printers offer the ability to manufacture extremely accurate parts in a shortened manufacturing time and the capability for remarkable detail in part design. Pulesheng Technology is the champion currently in this battle of advanced technology focusing on high-quality metal 3D printers.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.