Interested to learn how metal binder jetting can make factories better and faster? Well if yes, then you have come to the right place! That’s where Pulesheng Technology comes in, here to guide you through this exciting new product forming from metal. Learning more about how this metal 3d printing filament technology works can give you insight into how it simplifies manufacturing processes and improves efficiency.

The work of making things from metal is not very easy. Metalworking is a long and complex process where metal is shaped and parts are assembled together to make a final product. However, the introduction of binder jetting technology has revolutionized this entire process for the better now. And this method enables the factories to build metal pieces in numerous hours instead of days or even weeks! This online 3d printing service allows products to be generated significantly faster, helping organizations meet customers' demands.

The advantages of metal binder jetting make it a suitable choice for factories. The huge upside is it very very quick and precise. The speed helps to reduce the time it takes to produce items, consequently taking costs down as well. Factories can save money and use their resources more wisely when production is quicker. It binder jetting is also flexible and can work with various types of metals, which can be useful for producing everything from simple items to more complex products.

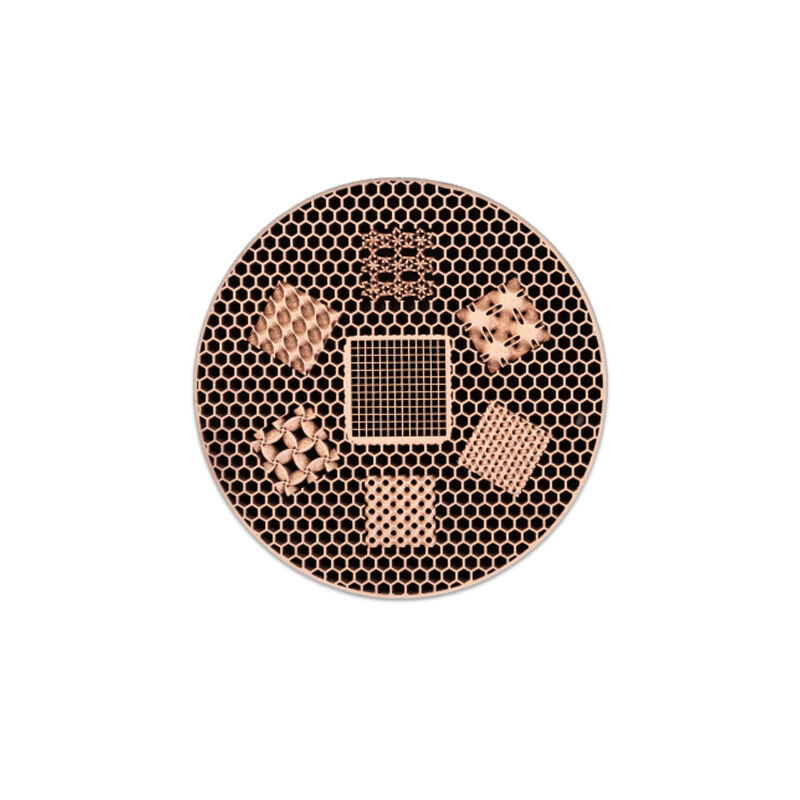

Metal binder jetting has some unique advantages that make it especially useful for many applications. In fact, it is capable of forming detailed geometries that are often difficult to achieve with other techniques. This skill of creating distinctive and complex pieces widens the horizon for innovators and engineers. print 3d on demand binder jetting guarantees that every single part produced be of soaring quality and highly homogenous. That consistency is vital for factories that seek to produce products that they can trust.

But, how does binder jetting technology work? It's quite simple! Step one is to create a "green" part from tiny cubes of metal powder. These pieces are glued together with something called a binder. After green part is formed the next thing we do is to heat it to a high temperature. Heating these metal powder pieces together at certain temperatures causes them to bond fusing them into a strong fully functional metallic part. The customizable 3d prints process of cutting edge technology is efficient and provides the desired quality items required in their trade.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.