Have you heard about 3D printing? It’s just a super cool technology, and it allows us to create stuff in a layer by layer printing kind of manner. Similar to building a toy or model piece by piece. Yet now we can even print metal parts, courtesy of a company named Pulesheng Technology. This is excellent news for a lot of firms that require great and difficult parts for their devices as well as devices. The advantages of printing metal parts rather than making them the traditional way are countless. First, it’s far quicker and less expensive. When we create metal parts in the classic way, we usually have to make them from plenty of metal blocks, cut or chiseled. It can also be a time-consuming and costly process. However, with 3D printing we can create a digital file or plan of the part that we want. Plan setup is available for anywhere from only few hours to all of us a few days — we can print it in our entire glory. Thus, it saves time and money for the companies too.

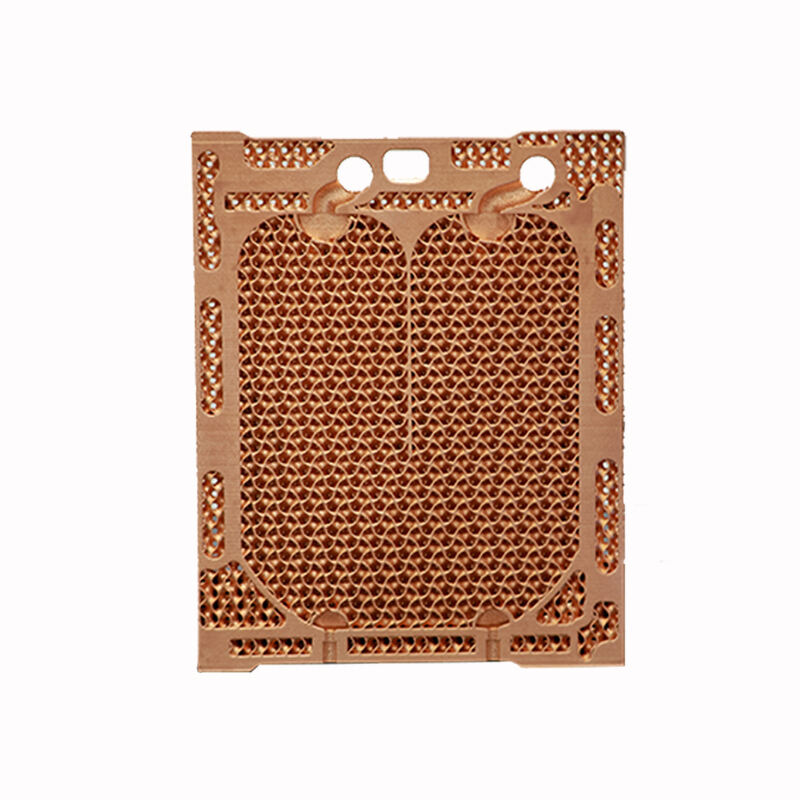

Printing of metal parts is good for another reason as well; it can build finer more complex shapes. Because some designs may be too complex, it can be hard to create them with traditional methods. That's what is so cool about 3D printers; they can do complex designs and patterns that a human could not do easily or at all. That means we can come up with more interesting ideas for components and build those. A further benefit of metal print is we also become much more efficient. In conventional methods of making parts, there is often a considerable amount of unused material that gets left behind. Money is not the only issue when it comes to this type of waste — it’s bad for our planet as well. Another advantage of 3D printed parts is minimizing waste, saving both your pocket and the planet. It’s like tidying up after ourselves and not throwing away the good stuff.

Additionally, customizing parts for specific machines or tools is much easier with 3D printing. That means we can build pieces that are an exact fit, which helps avoid issues that may arise otherwise if a piece isn’t fitting properly. It also means we can cranking out parts a lot faster.” Previously we would have to make a new mould for each individual part which was both time and labour intensive. Now we can simply update the digital blueprint and print a new piece in no time.

Indeed, some companies have already been using 3D printing to produce parts for their machines. For instance, the aerospace industry can use 3D printing to manufacture complex engine components that enable airplanes to fly safely. 3D printing is also being used in the medical field for making customized implants for patients that can be molded to fit their bodies perfectly. It demonstrates how 3D printing is useful in various industries and can have a huge impact.

So, what are the fundamentals of how 3D printing works? We generate a digital blueprint of the part we wish to print. We do this with special computer software that allows us to shape the part in great detail. The plan is prepared, fed into the printer, we press the print button. The printer then creates the part that is printed one layer at a time. Instead, it uses a special metal powder — and a laser — to form each layer perfectly.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.