Have you heard of tantalum? More than just a metal, tantalum is a high power material known for its binder jetting exceptional resistance to metallic malleability and corrosion. It is therefore very durable and can last a long time without getting damaged. We can actually do something much more exciting now: use tantalum in a completely new way through a process called 3D printing to build parts out of tantalum!

Probably the largest way in which tantalum 3D printing is already making a significant impact is in the medical field, particularly in regards to medical implants. Doctors used to have to rely on older technologies to make patients implants, which could be painful and uncomfortable. Such a system often forced patients to endure a multitude of not easily obtainable procedures. But now with 3D printing, physicians are able to manufacture unique parts that are tailored to each patient. This print 3d on demand means the implants can perfectly fit a person’s body, resulting in a much better experience for patients throughout the whole process.

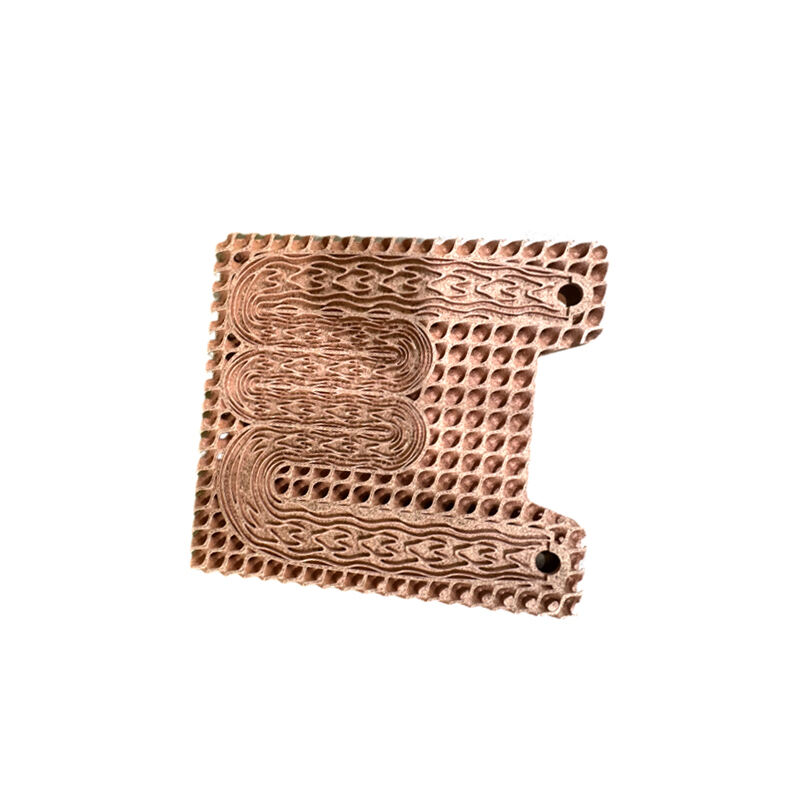

And the other great thing about tantalum 3D printing is it is very versatile! It is very strong, allowing parts made from the metal to withstand high levels of stress or pressure without breaking. For instance, if a part is found in machines or tools, it must be durable. Tantalum is perfect for this! It 3d printing suppliers also performs well under challenging conditions, such as when it encounters strong chemicals or extreme environments. This makes tantalum ideal for a wide range of products.

3D printing is transforming the manufacturing process, and tantalum is paving the way for this transformation. When parts can be printed on-site and on-demand, it helps to reduce waste, which is crucial for the environment. This allows them to produce less waste material that 3d print on demand would otherwise have to be discarded. It also allows them to help clients faster and more efficiently while keeping up with their workload. This will save time and resources for the manufacturers who will be able to make parts on demand. This is a faster way of creating things, and it is also better for our planet!

Tantalum is now a major component in making green solutions. It is a unique metal that is not as easy to find and mine. But with the use of 3D printing technology, now we can also get away with less tantalum in the manufacturing process. That metal 3d printing services a big deal because it will allow companies to use less new materials that are currently hard to obtain. Instead, they can shift to a smarter and more sustainable use of materials. Solutions that are good for the planet need to be identified, and tantalum is the enabler.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.