3D printing is a unique technology that is transforming the way we manufacture in many ways. But it is already helping sectors such as health care and manufacturing. You can create so much. Toys, implants, even an entire house if you have a 3D printer. This means that the potential of what we can build is virtually limitless. Perhaps one of the fine points of 3D printing is personalization of what you make. This means you can create products that are uniquely yours. Usually, when making things in a classic way, a lot of the same piece is produced which makes it difficult to create one of a kind things. So say you really want a toy that involves your favorite colors or shapes, maybe that will be hard to find. But now, with 3D printing, special items can be made just for you. This is particularly useful in healthcare, where patients across the board, but specifically in custom devices and implants, are requiring niche devices to be made so they can receive better fitting implants for the best care.

3D printing is revolutionizing various sectors in many novel ways. For instance, within the car industry, manufacturers use 3D printing to make parts that are lighter and more robust. This also helps make cars faster and more environmentally friendly, which is good for everybody. Using less materials helps us be more resourceful while helping keep the planet clean. In the medical field, 3D printing is used to cure patients by designing personalized devices. This allows for doctors to precisely tailor what patients need without the use of generalized solutions. For example, say a patient requires a special arm or leg, 3D printing allows for the equipment be made exactly for him/her. This improves patient outcomes and reduces healthcare costs as they received appropriate treatment at the outset.

If a company decides they want a toy, they can make a 3D printer with a model. They can take the toy out for a spin with kids to see if they even like it and make adjustments if necessary. That gives businesses an opportunity to test out what sells before producing a lot of toys. This allows them to identify issues, and prevents them from making a lot of bad toys that nobody will want to purchase.

For instance, a jewelry maker creating beautiful detailed designs, they can optics out a 3D printer. They can produce rings or necklaces that feature patterns and shapes that would be nearly impossible to create by hand. Then they can use those designs to create molds that can produce many pieces with the same design. Aside from the initiative of making every piece of jewelry identical and perfect like the other.

The best part is that 3D printing can create objects of all sizes. The machine can whittle away at everything from minuscule jewelry to massive, lifesize sculptures. This only goes to show how limitless the world of 3D printing can be. You may make little things to wear or large things to decorate your home.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

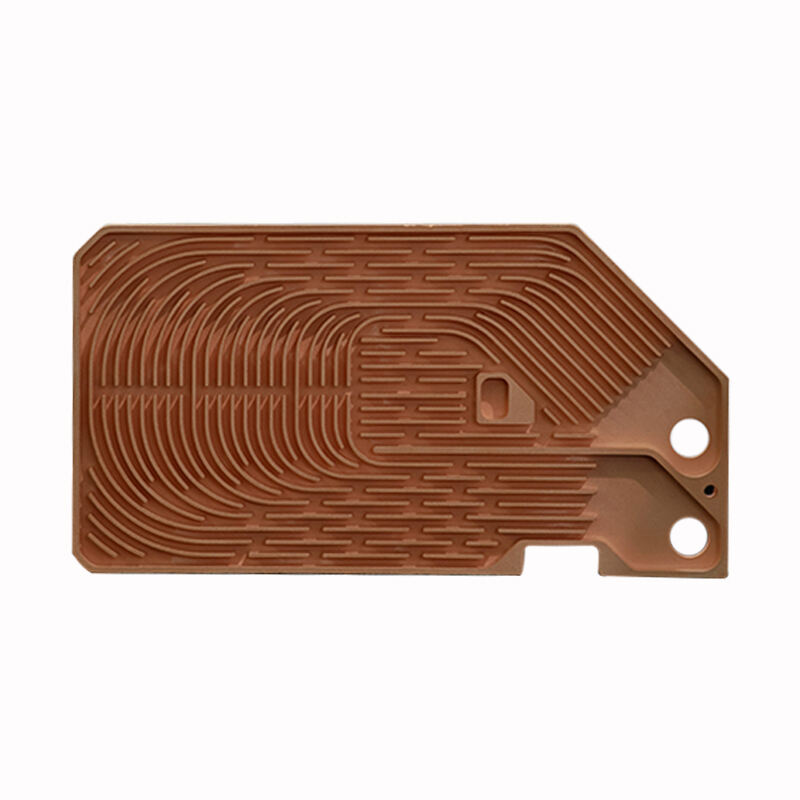

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.