When you are getting ready to 3D print a file for printing services, there are many things that people do wrong! These can result in unacceptable results or even expensive mistakes when working on your projects. To make sure you don't fall into these traps and achieve the best possible 3D prints, I've made this list of useful tips for beginner (and advanced) users. By taking note of these tips, you will take full advantage of the 3d printing service on offer and get your files ready to print in the highest quality possible.

The 5 Most Common Errors in Preparing an STL File for 3D Printing

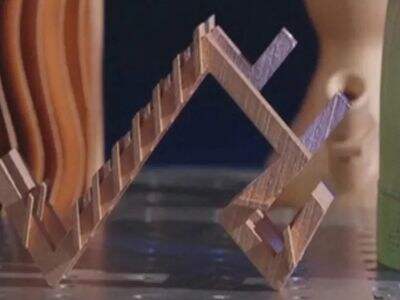

3D Printing seems like it should be easy – there is a file and you print it right? One of the most common mistakes is not taking file format as seriously as you should. There are different file formats for various 3D printers, so make sure you select the right one. Also you might want to take not of the direction your model is facing in your software as failing to will cause weak structures or prints. Another of them is failing to proof-read any errors in the design before taking it for printing. Such mistakes may result in wasted time and effort. By keeping these simple things in mind, you can help guarantee a more seamless printing process and a better final response.

Get the best results out of your 3D printer using these easy pointers

To get the best of your 3D prints, there are some easy tricks you can follow. First, just be sure to scale your design accordingly before you send it out for print. Probiems with scaling may cause prints to print out of shape or for parts not to fit. Second, you want to consider your level of detail in the design. At higher 3d for printing resolutions it will produce smoother prints with more detail. It also helps to optimize your supports structure so that it uses as little material and post-processing work as possible. Also consider the filament that you're using as well as different materials have different properties and need their own print settings. Finally, never forget to do a test print before laying down a full size job so you know exactly whats going wrong and correct it from the start. These are good practices that can help you obtain high quality prints and lower your project failure rate by integrating them into your file routines.

Unlock the full potential of your 3D printing service with file preparation

Setting up files the right way is key to making your 3D printing services investment pay off. Be sure and that your design is water tight and error free. This custom 3d printing will help you avoid printing errors and get more successful prints. Also think about how you position your object to lay down the layers to maximize layer bond and minimize support use. Aligning your design appropriately can also make your final print even more visually appealing. Be sure to check the scale and units when exporting your file so you don’t end up with a mismatch in size. It’s also important to select the appropriate file format that will work with your printer. Finally, name your files with the pertinent details (printing options, orientation etc) for a faster printing process. If you model and export your DFM-mandated files correctly, in place of these steps, using those settings as a template to export both parts will only require that you configure it once before exporting each file. You can expedite your workflow, optimize the efficiency of 3D printing services and obtain great results overall by following these easy steps while carefully minding how you set up for your file.

Don't make costly mistakes with your 3D printing

Mistakes made in 3D printing are expensive. Even if you have gone too far down the road on a project to turn back, later it is starting to get abundantly clear that nothing can be more costly than a mistake in time or resources and your chances of success reducing. One of the most frequent mistakes is being impatient with filing what file can be prepared. With a little extra time to ensure your designs are error free and as optimized as possible you can sometimes avoid costly reprints. Furthermore, not taking into account material constraints and printing settings may result in an unsuccessful print, as well as loss of material. You should study in advance the specs and limits of your printer to circumvent all that! Another important consideration is the position at which your design will be printed. Bad orientation can lead to weak prints, overhangs and ill-fitting parts that fail or print poorly. So next time you carry out a 3D print, remember these key flaws and proactively look out for them to minimize the chances of errors occurring and boost the success of your projects.

Prepare your files for best results 3D printing services

Preparing your files to 3D print is crucial for producing the most detailed and high quality 3d prints possible. To begin with, you can simplify too complex geometries and remove needless details which will help to make the print faster and better quality. If you can, divide bigger designs into smaller pieces for efficient print times and failure recovery. You should always inspect and fix mesh problems or holes in your model with Pulesheng Technology. These tweaks can alleviate printing headaches and bring you cleaner, more accurate parts. Also, adjust your print settings: layer height, infill density, printing speed to get the perfect results on this design. To get the most out of your design, play around with settings or materials to achieve the best outcome for what you want. Lastly, keep current on all 3D printing design trends and new technologies to continue optimizing how you prepare your files! If you work at it, never stop refining your files, and keep on top of industry trends you can offer the best for your clients in 3D printing processes.

Table of Contents

- The 5 Most Common Errors in Preparing an STL File for 3D Printing

- Get the best results out of your 3D printer using these easy pointers

- Unlock the full potential of your 3D printing service with file preparation

- Don't make costly mistakes with your 3D printing

- Prepare your files for best results 3D printing services