הדפסה תלת-ממדית של מתכת משנה את הדרך בה מייצרים רכיבים או חלקים למגוון רחב של אובייקטים, גם כאלו המאפשרים פיזור חום. באזורים חמים כגון בתוך מחשב או מנוע, המטרה היא לקרר את האזור שבו נוצר החום כדי שזוהי לא תתחמם יתר על המידה. עם זאת, בעזרת הדפסה תלת-ממדית של חלקים ממתכת, ניתן לעצב אותם בצורה מאוד מדויקת שתסייע לצננתם בצורה טובה יותר. הטכנולוגיה מציעה יתרונות ייחודיים מסוימים שעשויים לאפשר לBranchות לחסוך וליצור רווח על ידי פיתוח מוצרים מתקדמים בדרך היעילה ביותר. אחת החברות שהן בפרוזדור הקדמי בתחום זה היא Pulesheng Technology, אשר מציעה פתרונות טובים לניהול חום.

מאיפה תחפשו פתרונות סמויים לניהול תרמי באמצעות הדפסה תלת-ממדית ממתכת?

מאוד קשה למצוא מערכות ניהול חום מתקדמות מתכתיות מודפסות תלת-ממד באיכות גבוהה, כל עוד אינכם שוקלים חברות כמו Pulesheng Technology. הם מדגישים ייצור של חלקים שפועלים כראוי וגם עמידים לאורך זמן. כדי להבטיח קבלת רכיבים אלו, על היצרנים למצוא ספקים בעלי ניסיון בתחום הייצור התעשייתי. ביקורות והמלצות של לקוחות אחרים הן נקודת התחלה טובה. ניתן להשתמש בכך גם כמדד מסוים לאמינותה של החברה. יהיה אפשר לשאול שאלות גם בנוגע לחומר שנעשה בו שימוש בתהליך ההדפסה. יצרנים אחרים משתמשים באלloys או במתכות מיוחדות וחזקות יותר, שמסוגלות לעמוד בטמפרטורות גבוהות בהשוואה למתכות רגילות. תחום נוסף שיש לקחת בחשבון הוא תמיכת החברה בהזמנות מותאמות. כל מוצר הוא מיוחד ולפעמים חלק שניתן לראותו כאוניברסלי לא יעבוד. לדוגמה, Pulesheng Technology יכולה להדפיס לפי הזמנה וליצור עיצובים ייחודיים המופקים upon demand. לבסוף, תקשורת היא המפתח. הקשבה: חברה טובה תקשיב למה שאתם צריכים ותציע פתרונות בהתאם לניסיון שלה. עליה להיות מוכנה לענות על שאלות הקשורות לתהליך, לעלות וללוחות הזמנים. מערכת תמיכה חזקה מצד החברה יכולה גם כן לסייע בצורה משמעותית בהפחתת הקשיים בתהליך ולהפוך אותו ליעיל יותר.

למה הדפסה תלת-ממדית של מתכת היא פתרון יעיל לגאומטריות מורכבות של פיזור חום?

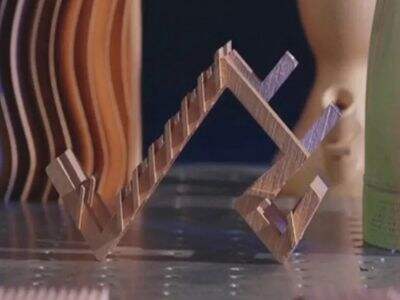

ניתן להשיג זאת בצורה הטובה ביותר באמצעות הדפסה תלת-ממדית של מתכת, שמאפשרת הדפסה של צורות מורכבות המסייעות בקירור באמצעות ייצור מוסף. השיטות המסורתיות היו מוטות במובן שהן הגבילו את שיטות העיצוב של חלקים. לדוגמה, בעיצוב של ריסר (פיזור חום), יש צורך בשטח פנים גדול מספיק כדי לקרר. בדרך זו, ההדפסה התלת-ממדית של מתכת מאפשרת יצירת צורות שיעילות לא רק מבחינת הביצועים אלא גם קלות משקל. עניין זה חשוב במיוחד בתעשיות שבהן כל גרם הוא חשוב, כמו תעשיית החלל. יתר על כן, היכולת האומנותית לעצב עיצובים מורכבים מאפשרת לרכיבים לאפשר זרימת אויר נוספת כדי לקרר אותם. חברת Puleshen Technology פועלת בתחום זה, ומספקת לחברות את המוצרים הנדרשים להנהלת החום בהן הן זקוקות.

היתרונות של ריסרים בהדפסה תלת-ממדית במכירה סיטונאית: מה עליכם לדעת.

בשוחקי חום אני מתכוון לחלקים שמאפשרים לדברים להתקרר. חלקים אלו חשובים ביותר ברוב המכונות, כולל מחשבים ורכבים. אחת השיטות הטובות באמת לייצור שוחקי חום היא דימות תלת-מימדי ממתכת. זהו התהליך אותו עוקבות חברות כמו Pulesheng Technology ביצירת שוחקי חום שהם יעילים, אך גם זולים יחסית.

יתר על כן, ישנן צורות נוספות שניתן ליצור בהדפסה תלת-ממדית. דבר זה, בתורו, יכול לשמש ליצירת גופי קירור יעילים יותר ללא הוצאות נוספות. דוגמה לכך היא שהם יכולים להיות בעלי תעלות מיוחדות כדי להבטיח זרימת אוויר טובה יותר ולכן להיות יעילים יותר. עיצובים טובים יותר = תוצאה טובה יותר, בכל מקרה, מצב של win-win. מכיוון שהדפסה תלת-ממדית של מתכת יכולה להיות חסכונית מבחינת חומר, והיא הרבה יותר מהירה מבחינת ייצור, בנוסף, היא מאפשרת עיצוב חדשני מה שהופך אותה לאופציה זהירה מצד חברות עוד יותר.

איפה ניתן להשיג ייעוץ מקצועי להדפסה תלת-ממדית מטלית על פתרונות תרמיים?

כדי להשתמש בהדפסה תלת-ממדית מטלית ברכיבי פיזור חום, עליכם להתייעץ עם מומחה. זהו תחום מחקר שלי, שאינו תמיד פשוט, אך קיימים רבים משאבים שיעזרו לכם ללמוד עליו יותר. Pulesheng Technology עושה עבודה טובה בתחום זה עבור אלו שרוצים ללמוד יותר sobre ניהול תרמי.

תוכלו לבחור קודם כל לנסות מספר אתרים. כמה אתרים מכילים סרטונים ומאמרים מידעניים המסבירים כיצד מבוצעת הדפסה תלת-ממדית מטלית. חומרים אלו לא רק יעזרו לכם להתחיל, אלא גם יסייעו לכם להתרגל לסוגי החומרים שניתן להדפיס ממתכת. למידה דרך צפייה במדריכים היא גם מהנה, ואתם יכולים לענות על שאלותיכם בעצמכם באינטרנט על ריבוי שאלות העולות.

לבסוף, במקרה של עזרה אישית, ניתן לשקול ליצור קשר עם חברות כמו Pulesheng Technology. הם מסוגלים להציע הדרכה מקצועית בהתאם למה שעובד בצורה הטובה ביותר עבורכם. בין אם אתם מתחילים או מומחים, העזרה המקצועית תוביל להבנה וליישום טובים בהרבה של הדפסה תלת-ממדית של מתכת בניהול תרמי.

שאלה אחת שהועלתה במאמר הייתה מהם מגמות ההדפסה התלת-ממדית של מתכת בחלקי פיזור חום?

כולם מעודכנים בהדפסה תלת-ממדית של מתכות, וחשוב שתהיו מודעים למגמות האחרונות, במיוחד בתחום פיזור החום, למשל במשפרים. אחת הקבוצות הללו היא Pulesheng Technology, שנמצאת כבר בחזית של העבודה המהפכנית הזו, וגורמת לנו לחשוב מחדש על מה שניתן להשיג באמצעות טכנולוגיה זו.

לבסוף, הדפסה תלת-ממדית של מתכת הופכת להיות אוטומטית וחכמה יותר ויותר. כיום, גם למכונות יש חיישנים ותוכנות שמותקנים כדי לעקוב אחר ההדפסה בזמן אמת. בכך נוכל להבטיח שכל חלק יהיה מושלם. האוטומציה גם מקצרת את זמן הייצור ומקטינה טעויות אנושייות, מה שאומר שיותר קל לחברה לייצר במהרה בקרני חום באיכות גבוהה.

תוכן העניינים

- מאיפה תחפשו פתרונות סמויים לניהול תרמי באמצעות הדפסה תלת-ממדית ממתכת?

- למה הדפסה תלת-ממדית של מתכת היא פתרון יעיל לגאומטריות מורכבות של פיזור חום?

- היתרונות של ריסרים בהדפסה תלת-ממדית במכירה סיטונאית: מה עליכם לדעת.

- איפה ניתן להשיג ייעוץ מקצועי להדפסה תלת-ממדית מטלית על פתרונות תרמיים?

- שאלה אחת שהועלתה במאמר הייתה מהם מגמות ההדפסה התלת-ממדית של מתכת בחלקי פיזור חום?