Additive manufacturing binder jetting relies on special computer programs — known as computer-aided design, or CAD, software — to design models of the objects we want to create. These models are the templates where they tell you exactly how the end product needs to be. Once we have the digital design, we can create physical objects by incrementallyAdding material layer by layer. One layer gets added at a time until the object is finished. It’s called additive manufacturing because we’re adding material on top of itself in layers, as opposed to removing material, like traditional manufacturing does. Additive manufacturing is amazing in the sense that we can customize and tailor products that meet our needs exactly. For example, we could make a unique piece of jewelry just for you, or a complicated part for a machine that must fit precisely. This is extremely beneficial because it allows us to make one-of-a-kind things that you cannot purchase in stores. It also has the added benefit of being waste-reducing. Often in traditional manufacturing much of the extra material is discarded, whereas with additive manufacturing we use only the amount of material directly required to construct the product. The aim is to be ecologically advantageous as we use less material and hence less waste.

But there are also the downsides of it. Additive manufacturing binder jetting can be more time-consuming and expensive than regular production processes. Because it requires time to make each layer, and some materials can be more costly to work with. Another thing is that not every material can be used for additive manufacturing so, sometimes, we have to limit the range of materials to the ones that we can work with effectively. Additive manufacturing is being used across various industries. For instance, you can make unique jewelry with one-of-a-kind and special shapes, colors, and designs that you cannot find anywhere else. Which can give people one-of-a-kind jewelry, We can also manufacture other items such as airplane parts, in addition to jewelry. Such parts could be stronger and cheaper to manufacture compared with conventional parts. Additive manufacturing can help us ensure that airplane components are both lightweight and strong, which is critical for flight safety. In the automotive industry, we can use this technology to manufacture parts for your car that are lighter and stronger, thus making them more fuel-efficient and safer.

Binder jetting Additive Manufacturing: Just the Beginning. Researchers are investigating new materials — including metals — which will open up many more possibilities for what we can create. He, therefore, began pondering the possibility of printing metal parts similar to the way we print plastic parts. A key area of development is multi-material printing, which allows us to combine multiple materials in one product. This week we are to do more complex designs. Algorithms will play a huge part in making the production process faster, easier, and cheaper, and the introduction of new CAD software and automated machines will be used in conjunction with 3D printers. It means that one day you will be able to produce awesome products in your own home.

The huge benefit of additive manufacturing with binder jetting is that we don’t need costly tooling and molds. They can also be very expensive and time-consuming to develop. Additive manufacturing can save us on time and money. That allows us to build complex products in less time than it was possible before. Additive manufacturing is also revolutionizing manufacturing because it will be possible to create designs that were likely difficult and even impossible to produce with traditional methods. We're also able to produce small amounts of products at no extra cost, which is good for businesses who want to do small runs of special products.

China Pulesheng Technology believes this will be the future of additive manufacturing using binder jetting. They are constant students of cutting-edge research and innovators, developing new technologies that enable us to achieve what we never thought was possible. Pulesheng Technology Industry will continue to develop innovative and easier used technology which will transform the product mode as the industry is developing and innovating.

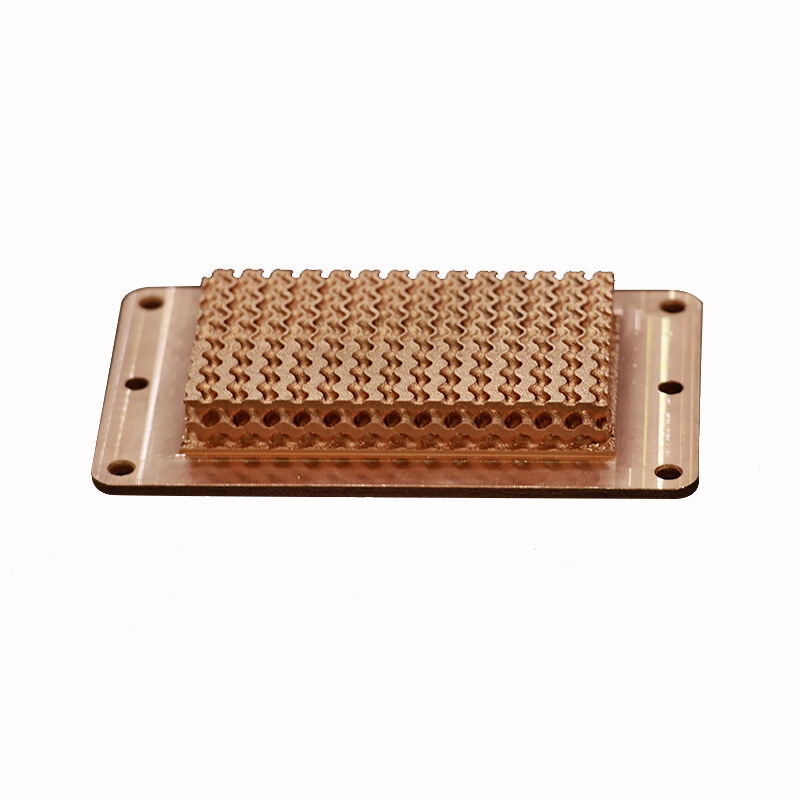

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.