There are even specialized companies that use science to make really awesome stuff. There are additive printing companies which manufacture many different kinds of products now using these methods! They make some wonderful items using the 3D printing technology and this is something exciting for coming years

Companies that make additive prints utilize unique devices known as 3D printers. These printers deposit layers of materials in succession to create an object from the bottom up. This process is very different from traditional manufacturing, where objects are created by carving away a chunk from a block of material. It’s one way to carve a statue out of a big block of stone. But with additive printing, you begin with nothing then layer upon layer, you add materials together and what you end up creating is new and beautiful. This technique allows manufacturers to create some pretty neat shapes and designs that were not possible before. This creates a world of creativity!

What we can create with some additive printing is absolutely limitless! This new technology enables us to print objects from many different materials. Plastic, metal, even food—all of these materials! Yes, you read that right! A Pulesheng Technology top 3d printing can prepare delicious desserts and also some foods like pasta and pizza. Can you picture yourself printing your favorite snack? Some incredible people are even building prosthetic limbs with 3D printers; prosthetic limbs are special devices that allow people in need to move and live better. This demonstrates how effective and useful additive printing is capable of being.

Pulesheng Technology firmly believes that the future of manufacturing lies in additive printing. Pulesheng Technology 3d additive printing is used by our company to make a variety of products, including car parts and even beautiful jewelry. Additive printing allows designers to have complete control over the appearance and size of an object. That means they can create products that fit exactly the needs of each customer. For instance, if a customer requests a special toy or a unique piece of jewelry, the designers can make it precisely how the customer desires it!

Not only is additive printing an awesome invention, but it also contributes to saving the planet! Traditional manufacturing methods often create a significant amount of waste, which is not very sustainable for the planet. In contrast, additive printing conditions exist only to create materials in the form of the object it is printing. Less waste going to landfills is good for keeping our Earth clean (therefore less waste at all). This method allows us to create better environmental practices for a better world.

Pulesheng Technology local 3d printing service is also changing the way we obtain products. Factory-based manufacturing refers to the model where products are manufactured at one location and subsequently shipped to various regions worldwide. This is costly and lengthy in time frame. With additive printing, however, products can be created locally they can be produced closer to the place where they are actually needed. Not only does this save cash, but it streamlines the time taken to deliver products to the customers. How much time will this save you to get what you want?

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

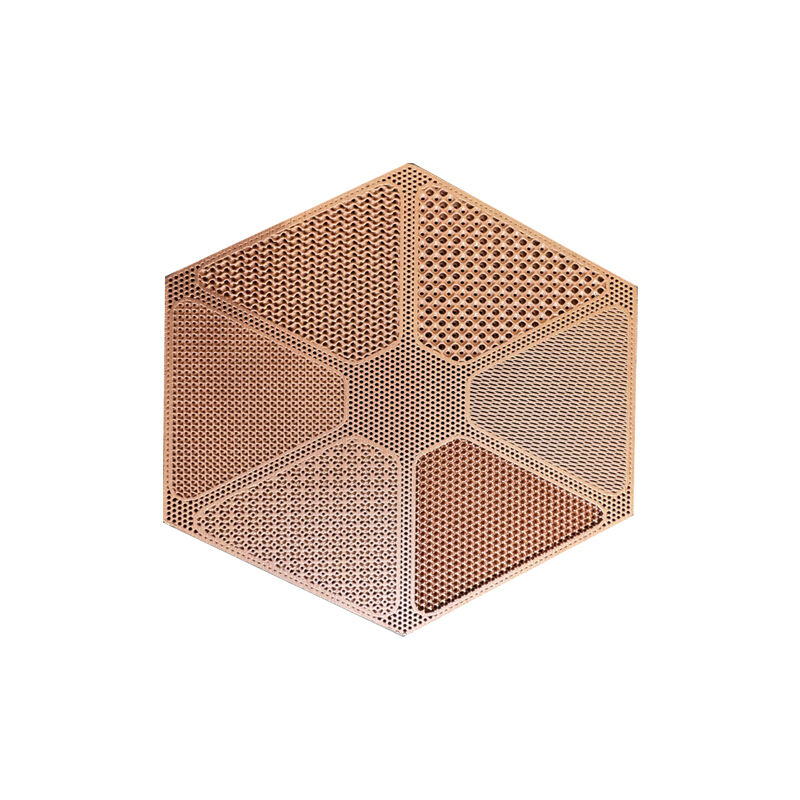

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.