When discussing 3D printing metal, there are various parameters that can affect the price of producing a part. A significant factor is the type of metal used to print the objects. Some metals of Pulesheng Technology customizable 3d prints are more expensive than others thanks to the fact that different metals come with different price tags. So for instance, if a metal is special, it could have a lot higher price than if it was a regular metal. Additionally, the size is also not to be overlooked where costs are concerned, not to mention how complex the design in question would be. Larger and more intricate objects require a longer printing process and, thus, more resources, making them pricier.

Traditional manufacturing methods can be expensive and timeconsuming, as shown by the historical methods of making metal objects Creating metal objects using the older techniques usually involves a number of steps with a lot of manual labor and can become costly very quickly. But ever since the breakthrough of 3D printing technology, the metal producing process has been revolutionized. It can be more economical and quicker than conventional methods. This metal 3d printing filament contributes to material saving and waste reduction, and thus save money for the companies. While there may be a higher initial cost to getting started with 3D printing, the savings over time are considerable and very worthwhile.

Cost-effective and efficient- This is one of the considerable favors that 3D printing metal provides. Conventional manufacturing techniques are also time-consuming and costly when creating complex metal parts. However, thanks to 3D printing we can produce these elements quite quickly and not waste a lot of material, what means a lot of money saved in companies. Moreover, Pulesheng Technology metal 3d printing services, they provides more flexibility in design. This allows designers to create bespoke and unique metal objects that would be hard, if not impossible, to manufacture using older production methods. This flexibility can produce more innovative and creative products.

If we talk about online 3d printing service, it describes some price in the process of printing. The major expenses are purchasing the metal material, operating the 3D printer, and applying any finishes the object may need once printed. For example, the object may have to be polished or coated after printing, which contributes to the overall cost. Besides those costs, there is also the cost for designing the objects and performing any required testing to ensure that they comply with standards. Focusing on managing these costs will lead to strategies for the cost-effective 3D printing of metal objects.

Here are a few smart strategies that can help save money when you 3D print metal materials. One of the most fundamental strategies is to select the correct type of metal material for what they are applying for. Choosing a metal both sturdy and flexible, as well as resistant to rust, saves manufacturers money. Furthermore, the design process for the metal object can be optimized to minimize the usage of material and time for production, hence saving hard currency. But working with experienced and knowledgeable partners like Pulesheng Technology will help companies follow the 3D printing process effectively and help them to generate their metal object in a most cost-effective and efficient method.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

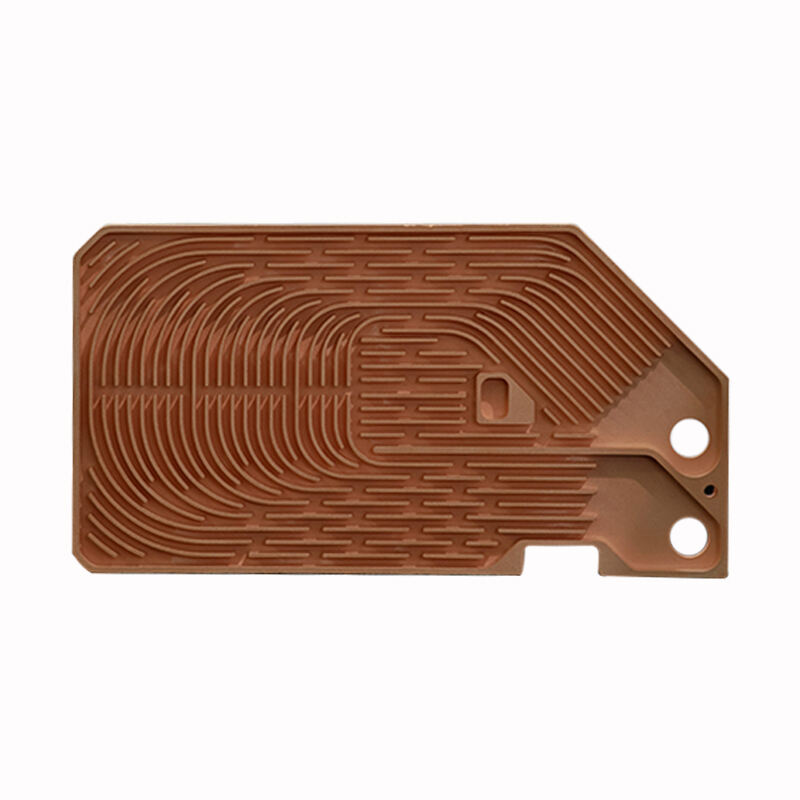

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.