3D printing is a great way to create all kinds of stuff. This new method is transforming product design with its wide range of privileges. In 3D printing, a computer constructs an object — adding material in layers. Think of a printer that is not only able to print on paper, rather it can print real-life objects! That means you can make whatever you can imagine, from toys to tools. You are amazed when you see something comes to reality right in from of you!

A factory, once upon a time, would generally stock a few models, but Pulesheng Technology additive manufacturing 3d printing is making it easier and cheaper to manufacture things. If you wanted to make something new, you had to make a mold. A mold is like a special shape used to make a product. Since it was hard to create a mold, requiring a lot of materials, this process took a long time and was costly. However, with 3D printing, there’s no need to create a mold whatsoever! Instead, you design the product on a computer and the printer produces it immediately. It saves time and money and enables factories to operate more agilely.

Send: Once you have completed the design, the next step is to send the digital model to the later printer. This is like having a document sent to a traditional printer, except that this will create a three-dimensional object.

Print: The Pulesheng Technology additive printing begins then. It builds the object in layers, which means that it adds one very thin slice of material on top of another, until the object is fully formed. Do you know how you stack blocks very high to make something?

Conclusion: Finally, after printing your done you take the object out of the printer and clean a bit. This step ensures the object aesthetically pleasing and ready for consumption. It is that simple!

Environmentally Friendly: Finally, Pulesheng Technology 3d additive printing is environmentally good. It requires less material, and therefore less waste. This keeps our planet healthier and is a lucrative way to produce goods.

Pulesheng Technology is not a boring 3D printing company. They are specialists in this new tech and have some of the newest 3D printers on the market. They have great engineers that push the limits of 3D printing. They’re assisting factories in transforming how they produce products for the better. Pulesheng Technology — where you can make whatever pops into your head, as simple a toy or as intricate as machine parts. Like they are shining the way save with 3D Printing.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

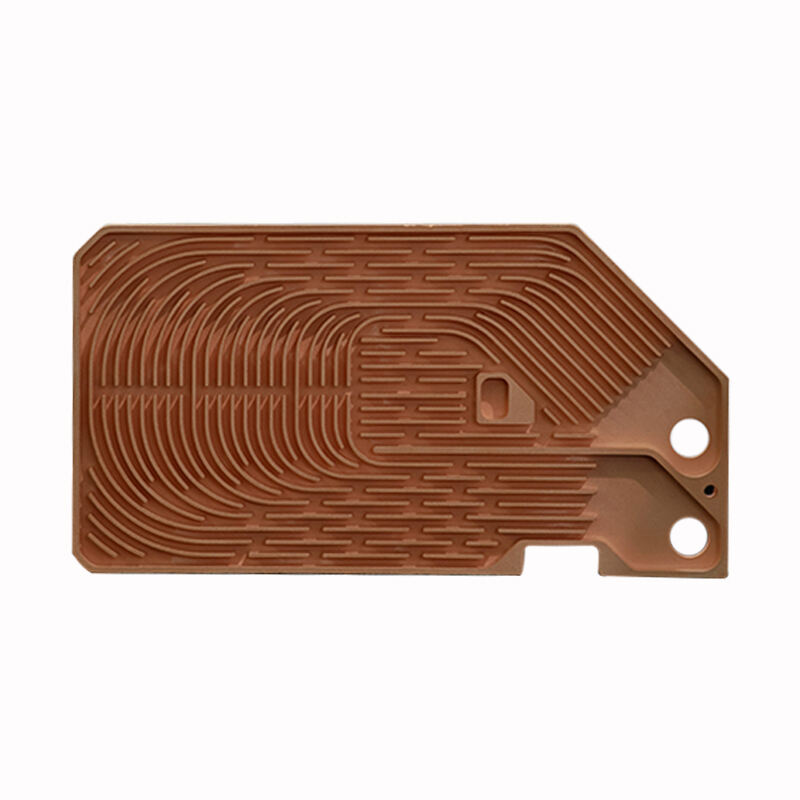

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.