Have you ever wondered about how factories produce all of the items we use on a daily basis? It can be in the same mould and typically is expensive and lengthy. But this can generate a lot of waste sometimes, and we all want to be a little friendlier to our planet, don't we? However, a new technology — 3D printing — is taking product manufacturing to the next level. This neat technology allows factories to manufacture things quicker, cheaper and with far less waste. It starts with a design on a computer screen. And then the fabric of a 3D printer uses this design to create the actual product.

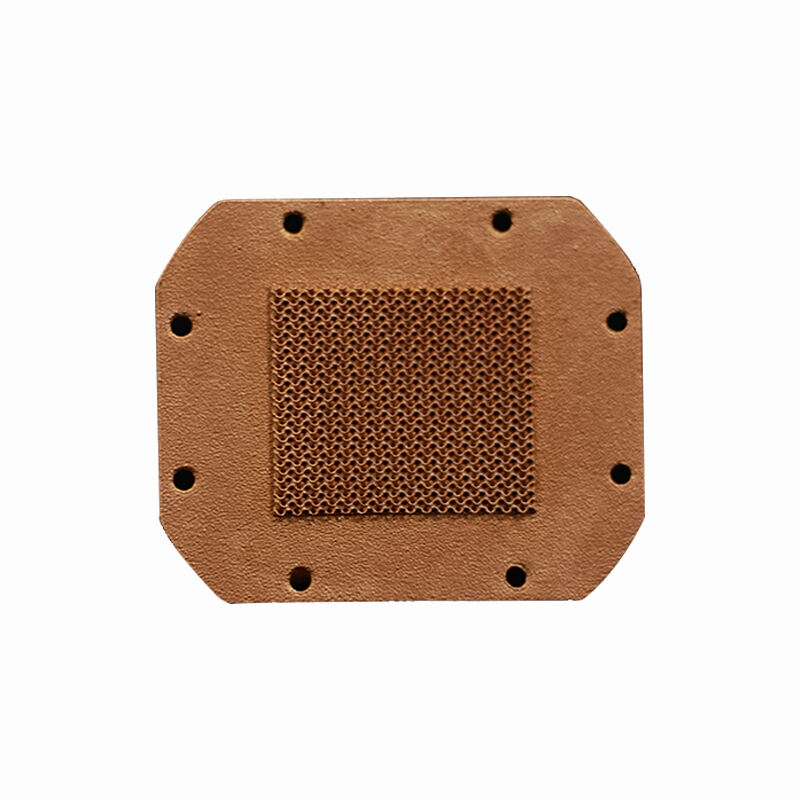

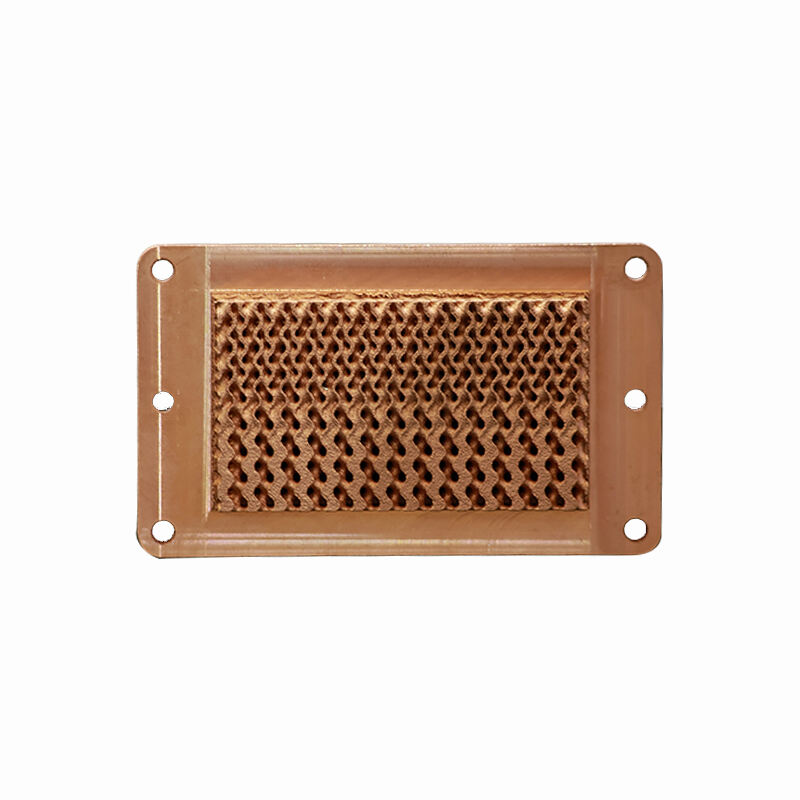

One of the most exciting elements of 3D printing is the ability to create shapes and designs that no traditional machine is capable of producing. A good example is a company called Pulesheng Technology that makes certain very special parts that must use large-scale 3D printing technology to produce with high precision. This means they are able to create complex designs that fit precisely with one another. This allows them to assist their customers in overcoming the most difficult challenges of manufacturing. Through this new technique, companies can become more fertile and productive in their manufacturing.

Factories used to produce mass quantities of the same product at once. For a long time this worked very well. But now that 3D printing has arrived, it's the game changers like Pulesheng Technology that are upsetting that old way of thinking. They are now capable to manufacture products specifically tailored to what each customer wants. This is why people can order things that are made for them as opposed to just being able to pick from a few different options. Many companies are still capable of making many products in quick succession. This power to able to customize not just keeps the clientele happier, but it can also help businesses to get differentiated from their competitors.

Honestly, this is just so incredible to see how much peoples' imaginations can be used via 3D printing, something we never even knew would come to be. Puleseng Technology enables companies to perform their own unique and comprehensive designs. They can create all sorts of product, from spare parts for airplanes to prosthetics for people, perhaps in need of prosthetics. The options are limitless. The only limitation is what you can dream up, or imagine creating. New opportunities to explore inventors, designs, and businesses

It is quite obvious that 3D printing is the future of manufacturing. This new manufacturing process isn’t just cheaper and faster, though — it’s also better for our planet. In this thrilling domain, Pulesheng Technology has become an industry leader, delivering intelligent solutions for the diversified needs of their users. Realistically, this spells a very bright future for everyone connected to this unique new paradigm shift in product making 3D printing. It helps us create better products that suit our lives and it helps businesses expand.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.