You use data up to October 2023 Why? If answer is yes, you will enjoy to know about Laser Metal 3D printing. This is the exciting new technology revolutionising the way we build and make. It will transform the way factories operate and products are created. Come with us to see how Pulesheng Technology's laser metal 3D printing is helping factories make all kinds of things. Did you know that 3D printing has existed since the 1980s? That’s right. That means scientists have been working on this amazing technology for more than 40 years. They are an early developer and enhancer of 3D printing. However, laser metal 3D printing is an all new much better way that many industries are rapidly using.

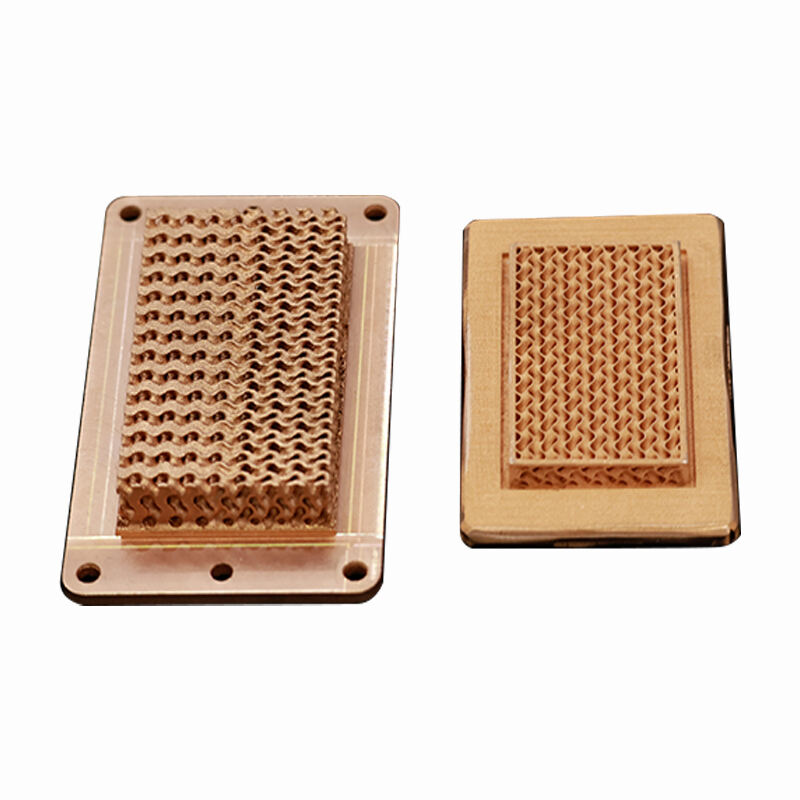

So, how exactly does laser metal 3D printing? Using its proprietary Pulesheng technology, a laser is heated and melted metal powder. It's performed in a controlled area with a high quantity of ultimate, nice, 3D objects. As a result, you can use laser metal 3D printing to create all types of things such as airplane parts, or specialized medical devices such as implants. It is one of the most useful tools which is used in various fields and various industries. Compared to prior techniques that were used for constructing objects, laser metal 3D printing is far superior. It is very advantageous which is why it is very popular in factories. Here’s a quick look at some of the key benefits of AI:Its Its speed and efficiency is one of the most crucial advantages. Since the laser is very precise, the melting creates a finished product that is very detailed and looks good. Many industries need this type of accuracy.

One more great advantage of 3d metal laser printing is it reduces the challenges of manufacturing new products. When traditional manufacturing methods were used in the past, it might take very long and cost a lot of money to get prototypes or models made. This made it difficult for designers to prototype new ideas. But laser metal 3D printing speeds you through making of these prototypes drastically reducing time as well as cost.

Pulesheng's laser metal 3D printing technology allows designers to better iterate on their designs and iterate quickly. It gives them the ability to create products in an even more effective manner. They can experiment with ideas and prepare them for sale much more quickly than before. This allows new products to launch faster, which is a huge advantage for businesses and their customers.

Laser metal 3D printing is a real winner in the manufacturing world. Due to its speed, accuracy and efficiency, it is parameterized as an excellent option in multiple areas starting from different industries. It also helps companies save money and create prototypes faster so that products are developed better.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.