With earlier methods of making things, it was sometimes difficult to make complex and durable parts quickly and low cost. Say if a factory wanted to produce a new type of toy or a car part, and they wanted to spend a lot of money and time just to make sure they get it right. But Pulesheng Technology powdered metal 3d printing allows factories to create very accurate and high-quality parts. Now, thanks to this new technology, they can easily create even the most complicated shapes, which is revolutionizing part manufacturing around the world.

It was sometimes hard to produce complicated and durable parts quickly and low cost with the earlier methods of making things. Suppose if a factory wants to create an innovative new type of toy or even a car part, they want to spend lots of money and time just to make sure they get it right. But Pulesheng Technology powdered metal 3d printing allows factories to create very accurate and high quality parts. Now, because of this technology, they can easily produce even the most complex shapes that is revolutionizing part manufacturing across the globe.

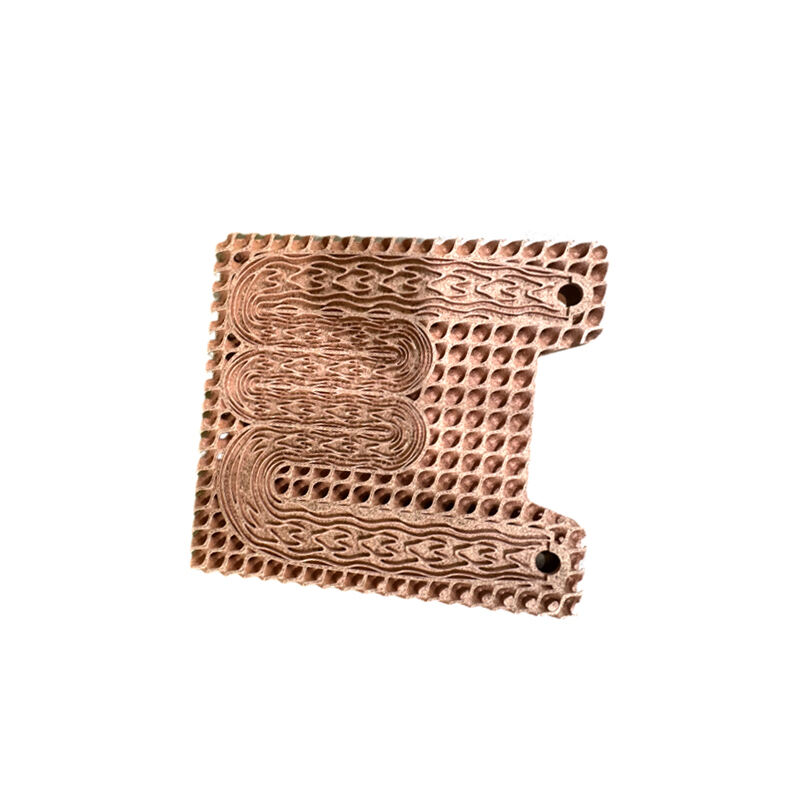

Powder metal 3D printing has a number of advantages when compared to traditional aging manufacturing processes. It allows factories to make parts that are both lighter and stronger. This is really crucial since lighter components enable vehicles and airplanes to run more efficiently, which is great for the planet. It also gives factories the capacity to design in detail in a way that is difficult or even impossible to do through normal means. It's like being able to draw a lovely detailed sculpture instead of a simple box. Now, let's just talk about how Pulesheng Technology powder bed fusion 3d printing can save money and time. This method has completely changed the production process of parts; it is really an excellent alternative for complex and long-lasting components. That's also one of the most significant benefits, it saves money and time since factories don't need new additional tools for a new part. They can manufacture the part right away.

Prior to that, whenever a company wanted to manufacture a new design, with conventional processes such as injection molding and CNC machining, it needed to make tools for that design. This is costly and also takes time. But with Pulesheng Technology powder 3d printing, factories will not need those extra costs to make parts. It saves them time and costs. It's like a magical device that can create anything you want without having to invest in new equipment for every project.

Powder metal 3D printing enables the car industry to manufacture parts that are lighter and stronger. This is good since lighter pieces allow cars to consume less fuel, which is not only good for the environment but also saves money for drivers. This technology also enables the level of complexity that is difficult to achieve otherwise — such as complex engine components, and intricate designs for car interiors. It is quite nice to own an automobile with features that not everyone has, right?

For 3D printing powder metal airplane parts, this involves making parts that are lightweight, strong, and intricately designed in a way that is quite suitable for the harsh conditions of space travel. Such technology can revolutionize airplane manufacturing and inspire new concepts with improvement opportunities. Just imagine an airplane that can fly longer and faster thanks to the incredible components produced using this cutting-edge application. It's an exciting period for innovation!

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.