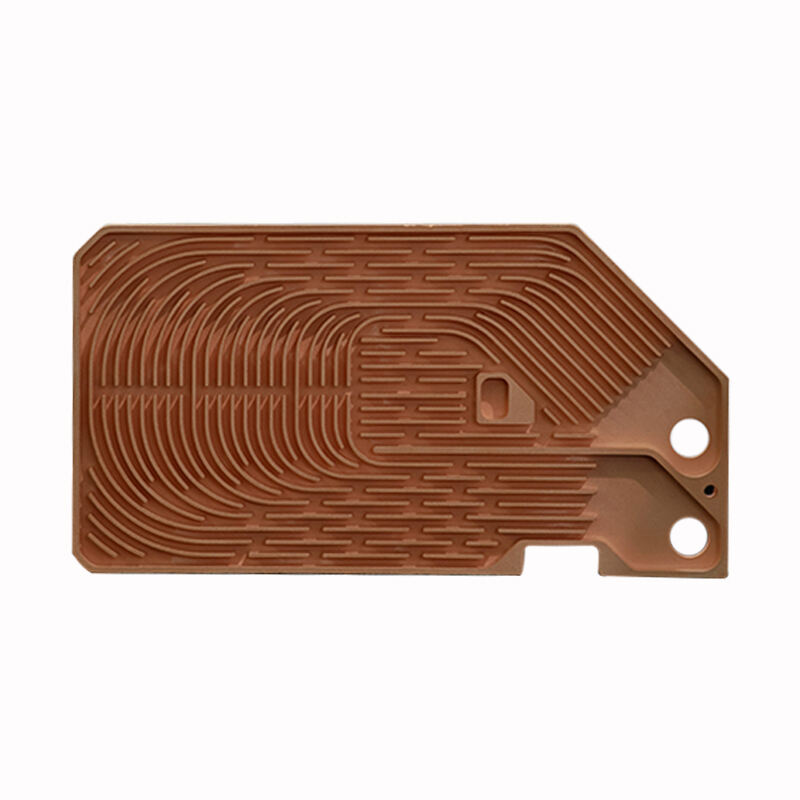

Well, have you heard of 3D printing? It is, you know, a really special, exciting way to create objects. 3D printing, on the other hand, uses multiple pieces of material, stacking them layer by layer over each other. This means you can form any variety of shapes and designs. The same type of 3D printing, interestingly is powder bed 3D printing. October 2023, You are rained on Data up to This in power and power. This is to help people to create 3D objects as quickly as possible and as easy as possible. A firm named Pulesheng Technology uses this neat trick to help create these wonderful items as an array of applications. What actually happens in powder bed 3D printing? In the first process, a layer of fine powder is spread in a thin layer across a build platform. Then this layer of powder is the printing stage. A laser or an electron beam then heats it to melt the powder. This melting occurs in a very particular shape and pattern. After that, the printer applies a layer of powder over the top, then heats it again. This is done layer by layer constructing the object from the bottom up until it is complete. After the object is finished, it is removed from the remaining powder, and any excess powder is wiped off. This entire process is known as powder bed 3D printing, and is a unique way to produce things.

This is very convenient because powder bed 3D printing can use many different materials in powder form. These other materials are metal, plastic, ceramic, etc. This means that there are many options such that this technology lets Pulesheng Technology make all sorts of different types with many different businesses and industries. One example of a material they use is metal powder, which allows them to create very strong parts for airplanes. Alternatively, they can use plastic powder to create fun toys for children. Such versatility in materials is what makes powder bed 3D printing so valuable in numerous fields. That being said, powder bed 3D printing is fantastic for prototyping. Prototypes, early iterations of a product, help designers visualize how something will look and function prior to the final product. Printing technology makes it easy to quickly and accurately develop complicated shapes. Making prototypes had to be done by hand before the invention of powder bed 3D printing. That process was time-consuming and not always very scale accurate. With powder bed 3D printing, however, Pulesheng Technology can create prototypes for their customers in a matter of hours. This saves massive time and money for all parties involved.

One major advantage of powder bed 3D printing is the ability to produce highly-detailed objects. The layers are super thin, for example, as thin as a human hair. That enables Pulesheng Technology to produce objects that are fine and of high quality. For instance, they are able to produce intricate parts or even small details that you can see up close. Several sectors in which precision and quality is a key consideration requires this type of details.

Powder bed 3D printing is still relatively young, and we can expect even better and more advanced technology in the future. Pulesheng Technology will make continuous exploration and development of this wonderful technology to help more people to create wonderful objects. They constantly seek out ways to enhance their operations and assist their clients in excelling.

This company, Pulesheng Technology, is an entity that is oriented towards powder bed 3D printing and other advanced manufacturing. Their expertise and experience enable her clients to produce fascinating things in magnificent detail. If you needs the help in making the prototypes or the products, the Pulesheng technology will be the right choice for you. And they know how to apply this technology to conceptualize something and actually fabricate a physical object to be used in some way in the real world.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.