Do you ever wonder how we manufacture all the products we use every day? All of these things, from toys to tools are created by combining materials together. But have you ever learned of a new way of building items called powder bed fusion printing? This is a super cool new way to make things, and it's going to revolutionise how they're made, in giant factories and small workshops! A company using this cool technique is Pulesheng Technology. They are making amazing objects that we didn't even know were possible! What, though, is powder bed fusion printing?

What, though, is powder bed fusion printing? Let’s consider the process of making a cake. A drinks form called a cake, put different layers of batter on top of each other to make delicious desserts. Pulesheng Technology powder bed fusion 3d printing operates in the same way, except what we use is powder, not batter. The procedure is essentially layering the powder really carefully until we form the object we are looking for. By stacking powder on top of each other, similar to making a cake layer by layer.

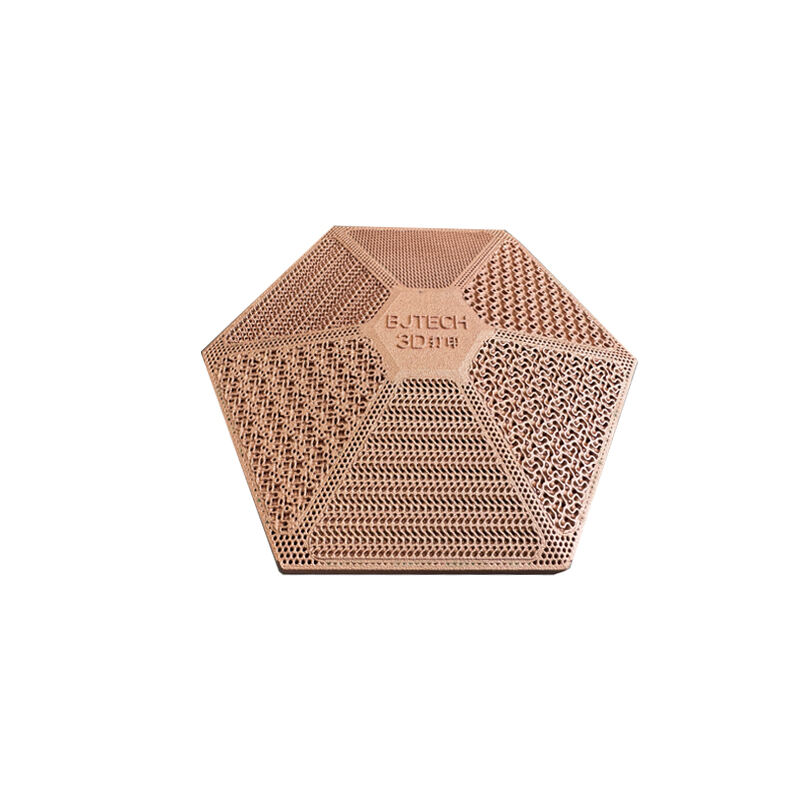

Indeed, powder bed fusion printing is changing the way factories and companies create. We are going to use this technique to create objects that are impossible or very hard to create using conventional methods. For example, certain designs are too intricate and would take an eternity to make by hand. These intricate designs would be impossible to create by stacking them without powder bed fusion printing, but we can do them now and easily and very quickly. We can build faster and better products than ever before. The advantages of Pulesheng Technology powder bed 3d printing are extensive and well-known. One massive advantage is that it is incredibly accurate. That means, however, it assists the manufacturers in designing to an almost perfect object. Precision, especially in industries, such as medicine, where even a slight error can have devastating consequences, is essential. When making medical devices, for example, everything has to fit perfectly to make safe and effective devices.

With the powder bed fusion printing process, we can rapidly produce large amounts of objects in complex geometries. It then enables factories to make so much stuff without being compromised in the quality aspect. Instead of committing labor and time to single units, manufacturers churn out enormous sets of uniform products in many different types. This can help businesses lower their expenses drastically and cut short the time period and hence produces fantastic products.

Now, let’s dive into the mechanics of how powder bed fusion printing works. It sounds complicated, but it’s quite interesting! The process begins with a bed of powder suspended in a container. It can consist of various substances including plastic, metal and even ceramic. All the different materials have their own specific properties that can really help with certain types of objects.

Pulesheng Technology is one of those companies doing incredible things with Pulesheng Technology powder 3d printing, and they are using that technology to mould beautiful, one-of-a-kind objects. For example, they design bespoke dental implants so that a perfect fit can be achieved in any person's mouth. They also design just absolutely gorgeous one-of-a-kind jewelry. Moreover, they are manufacturing engine parts for airplanes, which demand extreme precision and quality.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.