We at Pulesheng Technology, take great pride in utilizing advanced technology to manufacture customized components in accordance with the requirements. We achieve this through a process known as material jetting. This is an interesting process, because it uses special printers that create components one layer at a time, similar to assembling a puzzle. Today we’ll take a deeper dive into how 3D PRINTING works and why it’s so critical.

Material jetting is an intelligent approach that allows us to produce components with very fine details. In this method, our binder jetting printers squirt out minuscule drops of material on a flat surface. The drops are tiny, and as they reach the surface, they begin to take the shape of the part we want to build. Then, the drops are hardened solidified with a special type of UV light or other energy. This hardening process is important, as it allows the parts to retain their shape and maintain their strength.

Material jetting may appear straight to the layman, nevertheless it’s a extremely technical operation requiring an excessive amount of talent. These printers spray drops of material from a few microns or smaller. However, to ensure everything is working as it should, we must manage a couple of key elements. For instance, there's a limit to how quickly the printer can operate, and how hot the material can be when it exits. These little details are very important because they allow us to produce quality parts.

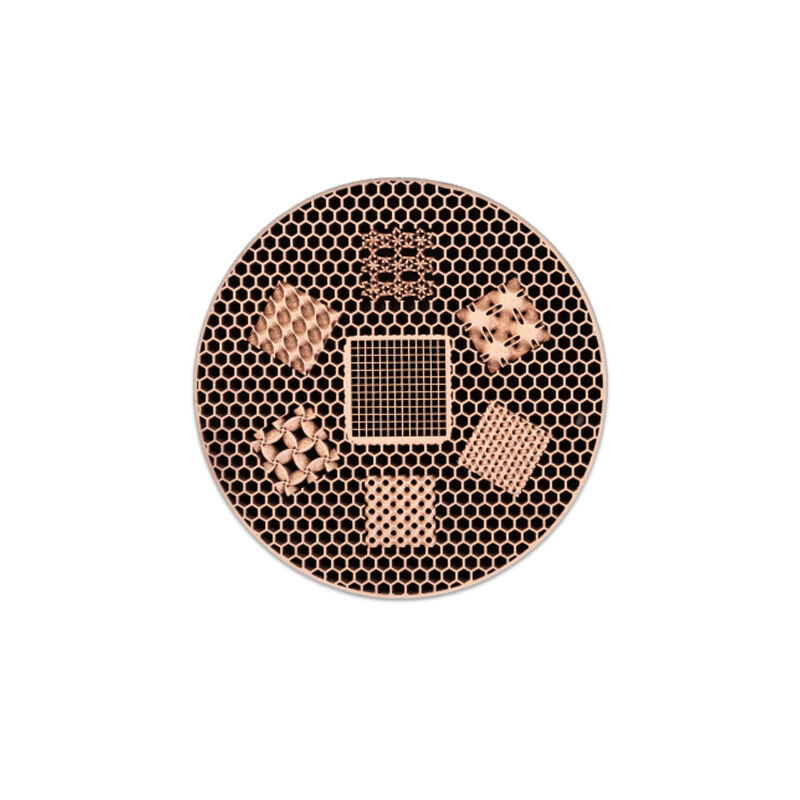

One of the most brilliant things about Pulesheng Technology material jetting is its ability to make very intricate designs. Since the process is so precise, it enables us to make very fine details that it would be really difficult, if not impossible, to make using other means. So think about what it would be like to make a small toy or piece of jewelry, material jetting can build that. Moreover, this metal 3d printing services is really fast, hence it allows us to produce your parts quickly and efficiently. This speed is extremely useful, especially during times when the quantity of orders that need to be filled is huge.

We believe that large-scale material production is going to revolutionize the way we manufacture products. Additive manufacturing is particularly suitable for producing small and complex components that are required across many industries, including healthcare, aerospace, and electronics. As large scale 3d printing is a digital process, we can modify a design very easily. We can quickly try resistance to a new idea or fix if we want to. It is very flexible, therefore making it a good technique for testing out new designs before committing to large number of parts.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.