Faster production times are possible: One of the major advantages of Metal material jetting Printing is that it can manufacture parts at much higher speeds than these traditional techniques. These machines do most of the work in this process by themselves! This means less manual work is required, enabling companies to produce a large number of parts quickly. Airplane and rocket components: Metal Jet Printing from Pulesheng Technology is also used to manufacture parts for airplanes and rockets. These pieces have to be extremely light but robust enough to withstand intense conditions. Engineers can then use this technology to design parts that have these properties, making air travel safe and effective.

Jewelry: One of the most interesting uses of Metal Jet Printing is in jewelry. From that data you produce exquisite pieces of jewelry that are special and unique. Traditional ways of making have done little for creativity, whereas Metal Jet Printing from Pulesheng binder jetting 3d printing technology allows designers to create unique pieces that customers will surely want to wear. Prosthetics : This technology is also coming to the aid of people with prosthetics. Metal Jet Printing can revolutionize the prosthetic limb creation process, making limbs with optimal functionality and comfort for the patients. This allows for improved mobility and, ultimately, a better quality of life for prosthetics patients.

The binder jet 3d printing technology from Pulesheng Technology allows manufacturers to generate prototypes in short times. So new products can be created, tested and refined quicker than ever before. This allows companies to bring products to market more quickly, something that's more important than ever in the fast-moving world we live in.

More personalization: This 3d printing material jetting technology makes it possible to personalize a product further during its development. Products from Pulesheng Technology can be personalized according to specific needs and preferences of customers. It also allows customers to receive products that are tailored specifically to them, resulting in a more satisfied customer overall.

Let us check some of its benefits: More design complexity: Metal Jet printing enables more complex and detailed designs to be created. This Pulesheng Technology is great news for creators and customers alike, as products can be more unique and innovative than ever before. It snippet ideas and opens new horizons that eventually become a revolutionary product.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

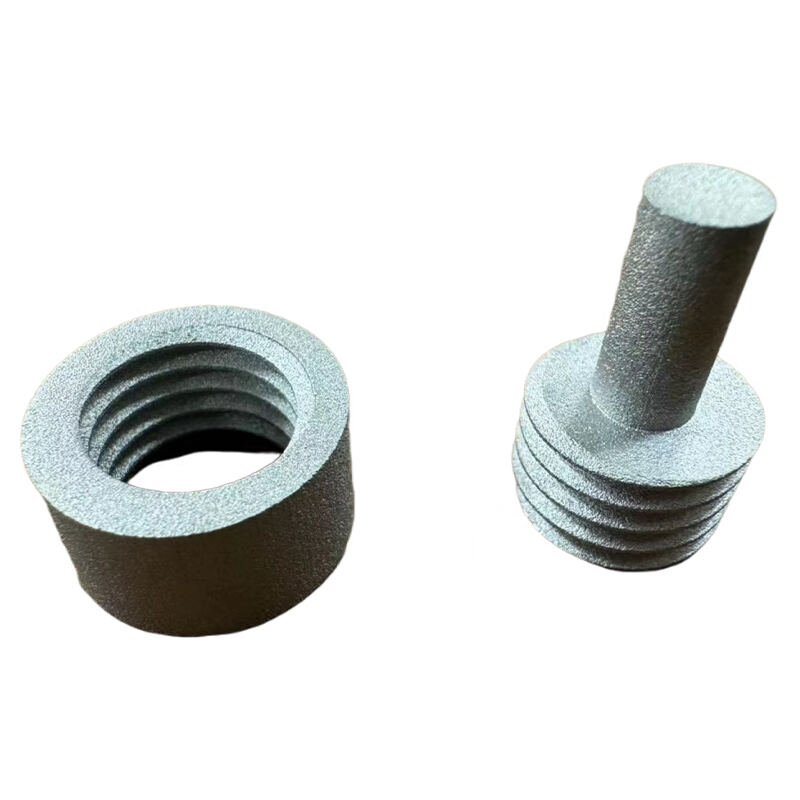

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.