Ever wondered how the stuff around you is made? You may have seen large buildings that produce many different types of products. Have you heard of something named 3D printing? It is an awesome technology that compounds materials in planes up to each other, sort of similar to playing with blocks. This time we are discussing a particular type of 3D printing known as online metal 3D printing. This kind of printing enables people to manufacture metal objects with only a computer and the internet. Isn’t that amazing? This new way of doing things is transforming the perception of manufacturing.

If you wanted to create something out of metal, in the past you had to go to a factory or a machine shop. There, artisans would go to work with their tools and machines, cutting and bending the metal until it met the desired specification. It might be much longer and need various instruments. However these days, with online metal 3D printing, all you need is a computer and an internet connection. That makes it a lot easier for everybody. Pulesheng Technology has already made a big leap in the metal 3D printing service online. They have websites that allow you to submit your own designs. They will then print it for you in metal after you upload your design. Which is wonderful since we no longer need costly tools and equipment, which means spending less time and money. No wonder there are people all over making things from home.

Companies such as Pulesheng Technology are making creating custom objects orders of magnitude simpler. You don’t have to be concerned about ordering bulk amounts and spending a good amount of money for something special. You can create unique, special iterations—quickly and at scale—with online metal 3D printing. It means your ideas can be translated into real objects more quickly than ever before.

However, one of the most exciting aspects of online metal 3D printing is that it unlocks so many different design possibilities. The traditional methods of metalworking often mean that there are limitations on what can be created. However, with online 3D printing you can design and print almost anything you can think of.

Online metal 3D printing they come with multiple different metals, including stainless steel, titanium, and aluminum. You can use these materials to make original designs for jewelry, ornaments and other objects. For example, you can have a computer program with which you design an object, you would have fulfilled control over its appearance. You can make your creation bigger or smaller, you can change its shape, you can add to it. This lends itself to unreal creativity and originality in the pieces that you create.

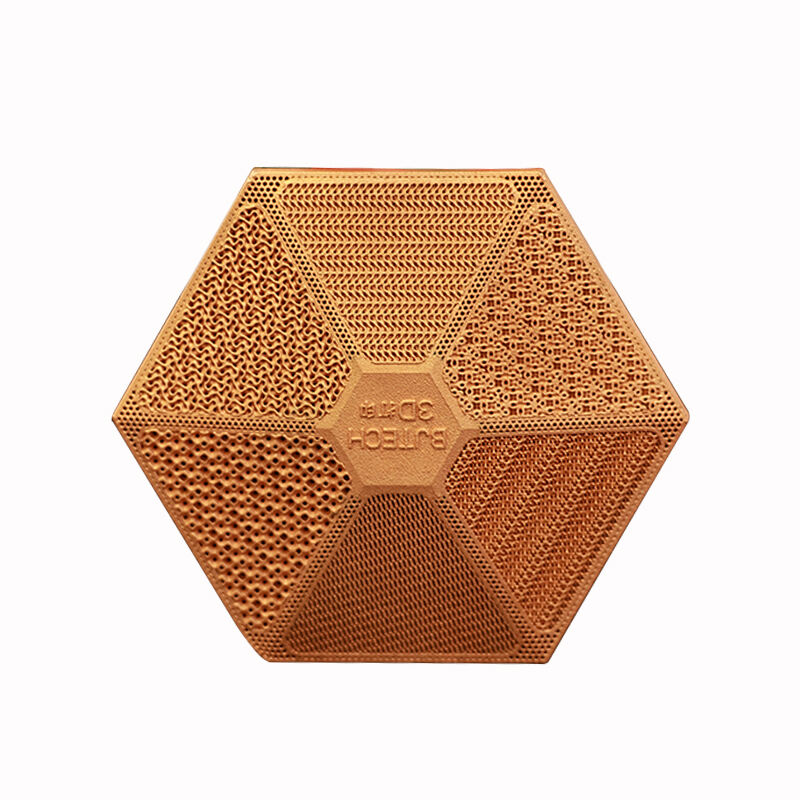

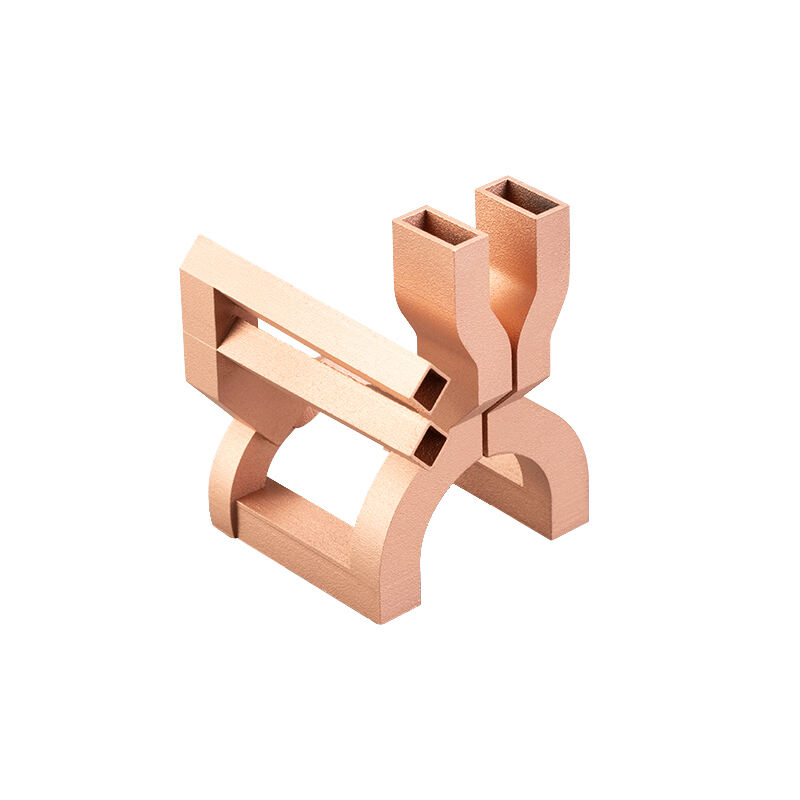

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.