Pulesheng Technology is at the forefront of transforming manufacturing through a nifty new technique called 3D printing. And this incredible technology expedites the creation of products. Whether it was designing something from scratch manufacturing it or moving it around the world it could take months or even years to produce something; now thanks to 3D PRINTING we can produce products like these in hours or a few days at the most. The key take here is how this is a real big what the obtain you.

This is a service that can take a long time to create and one of the main advantages of 3D printing is that it lets designers easily produce models. If designers come up with a new idea, they can create a prototype of it immediately. This allows them to put their ideas to the test to see if they will actually work. If something is off, they can modify and try again. 3D printing allows you to take a concept or an idea and convert it into a complete product much more quickly than traditional means. uses state-of-the-art metal 3d printing services and equipment to fabricate precise and high-quality parts. We ensure that the components you order are tailored precisely according to your specifications.

Pulesheng Technology has 3D printing online ordering service available as well. That part is pretty nifty because that means you could have that piece sent to your home. Whether you need a single model or tens of parts to fit within a project, we’ve got you covered. Our 3D printers print parts with a diverse range of materials: plastics, metals, ceramics. Having that variety means we can create parts for various applications and industries.

Another awesome benefit of 3D printing is that it can produce custom parts. These are special parts tailored to the exact specifications that a business might require. This groundbreaking innovation is extremely useful for companies operating in need of exclusive parts for their unique projects. Rapid manufacturing allows for very quick and efficient means to manufacture these custom parts. This print 3d on demand helps not just with saving time but also minimizing the costs associated with traditional manufacturing methods. Businesses can take what they need without breaking the bank.

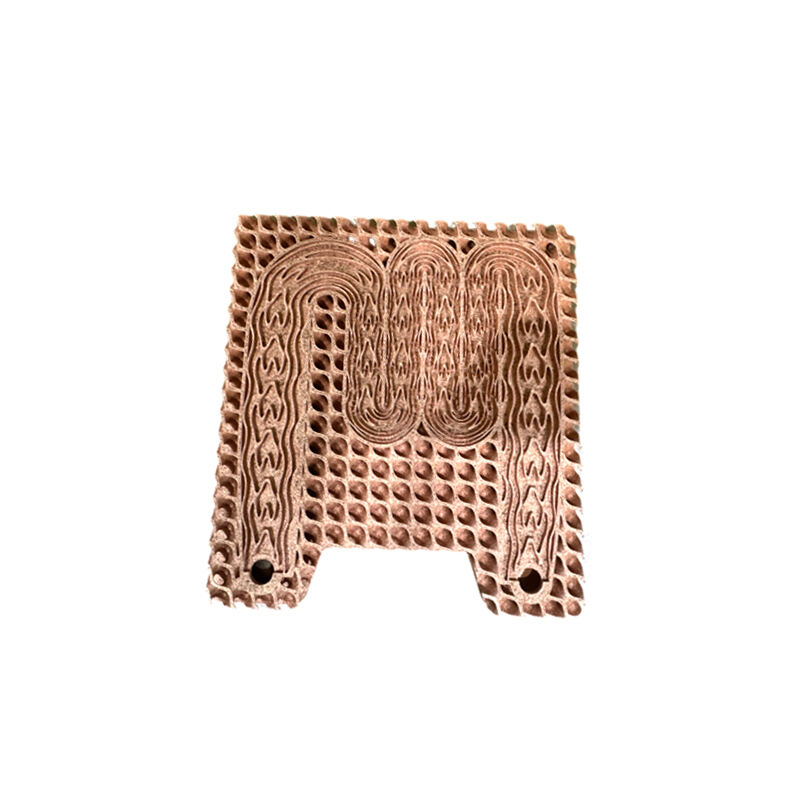

This technology has been proved worthwhile. First, it can produce parts with complex geometries that would be very difficult or even impossible to produce with older manufacturing techniques. Moreover, 3dprinting creates components with a high degree of precision and accuracy. This is particularly significant in fields like aviation and medicine, where even tiny errors can lead to disastrous consequences.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.