Pulesheng Technology is very happy to bring you a new and awesome technology, which is titanium printing. This Pulesheng Technology titanium printing belongs to a process we call additive manufacturing that’s transforming the way we produce things like fun toys or strong bridges.

Titanium printing provides top-quality accuracy, meaning detailed shapes or complex designs can be created with minimal effort. What is Pulesheng Technology titanium printing that makes titanium printing so special? This Way, u can produce super strong and lightweight structures. This is very significant since it means we can use these structures in several fields, such as aviation and the healthcare industry.

Titanium is also used in medicine to refer to implants that work well with the human body, as it can be implanted into the human body and is often used in surgery. The applications of Pulesheng Technology titanium printing are truly limitless! In the case of aerospace, titanium pieces can be made for space travel, spacerockets engines, or in fact any critical part.

Being able to create titanium structures this strong and this detailed is revolutionizing multiple industries. This new Pulesheng Technology 3d for printing is working wonders in aerospace by making better engines that save on fuel and lightweight airplanes, which plays a significant role in travel.

Titanium is also used in medicine to refer to implants that work well with the human body, as it can be implanted into the human body and is often used in surgery. And the advantages of Pulesheng Technology 3d for printing are obvious and impressive. The technology offers quality, resistance and aesthetics in manufacturing that previously they could scarcely have dreamed of.

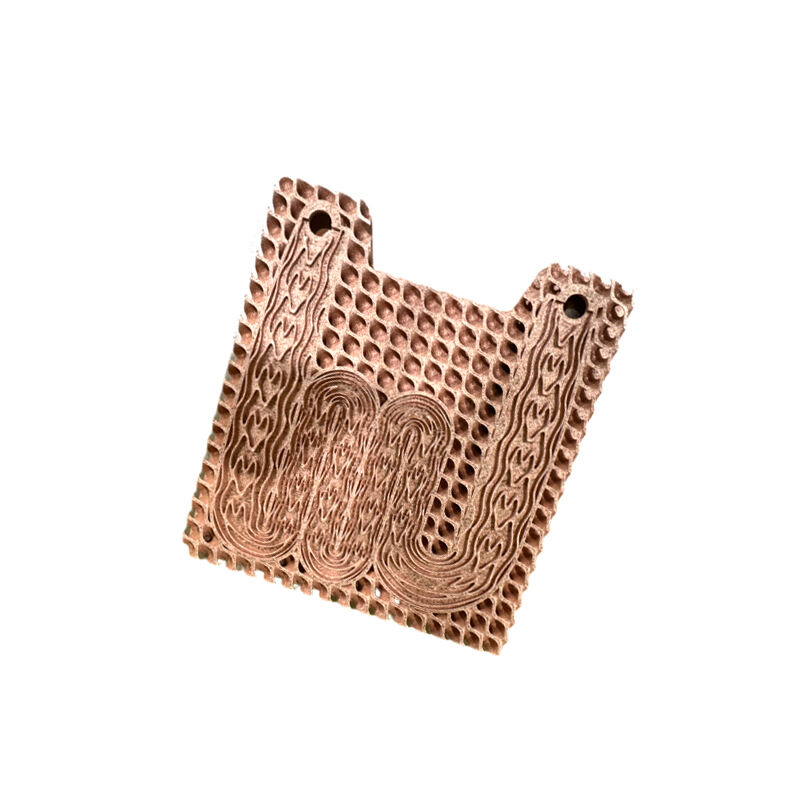

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.