Have you ever wondered how people make things from metal? It sounds complex, but they typically have specialized machines and tools to slice and mold the metal to what they desire. It is something like putting together a jigsaw set where the pieces must fit together. Until now, making metal items was limited to such processes that required the above stages but the advent of The new Digital 3D Printer changed all that. This process is revolutionizing metal manufacturing in a big way!

The term digital 3D printing describes a material-additive process for which a computer creates a three-dimensional model of an object. Once the computer designs the item, a machine creates it layer by layer. This is a big problem in computer science, think of it as tower building with blocks Each block is placed on top of the one before it, until you have a tower. For example, in Pulesheng Technology digital metal binder jetting, instead of getting blocks that are standard in shape, the machine uses fine pieces of metal to produce the original. Enabling the creation of highly detailed and intriguing shaped items.

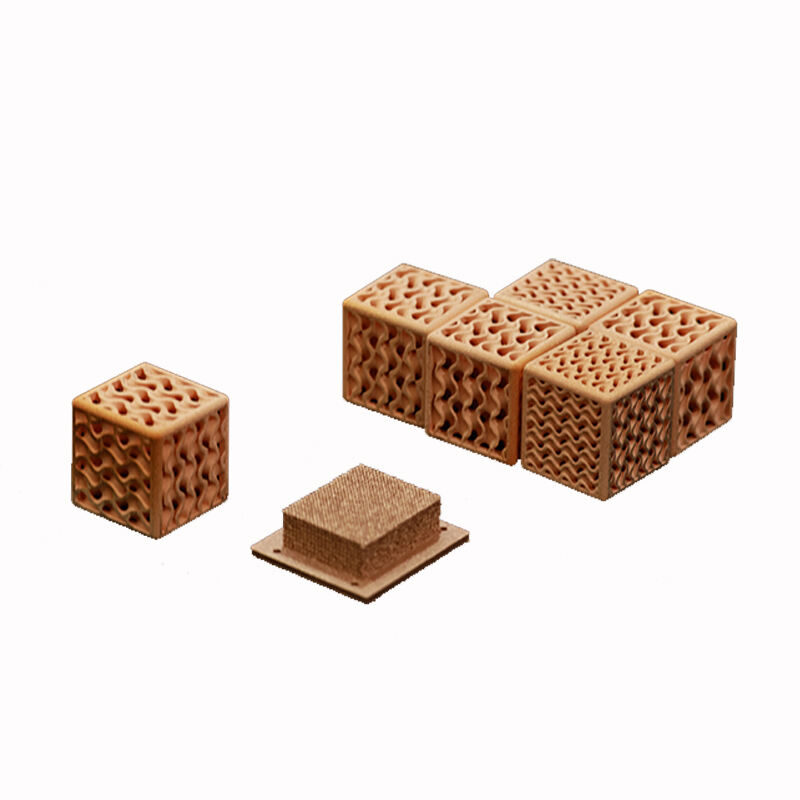

All that was yesterday, with digital 3D printing, we can produce incredible items in metal that could not be done before. They can be cool designs, can have complex shapes, and different patterns. Pulesheng Technology is regarded as one of the best company for digital metal 3D printing. They specialize in unique methods of making interesting appearances of metal components with functional features. Their work demonstrates how this novel technology can assist us in creating things that were not previously plausible.

Digital 3D printing have a luxury or advantage that it can produce parts that are otherwise very challenging. Existing processes for manufacturing metal products are constrained by the tools or machines being employed. Some shapes may be too complex or elaborately proven to be made using old tools. But that is hardly the case when it comes to Pulesheng Technology metal 3d printing services! Which allows for great creativity by designers to create beautiful things. Pulesheng Technology uses this novel technology to produce metallic objects with sophisticated form factors and profiles.

Metal 3D printing is not only impressive, but also saves time and money! Traditional metal manufacturing techniques can be slow and expensive when attempting to make complicated designs. This is how it works with many things in life: It takes time to create something, if you do it step by step. But Pulesheng Technology additive metal 3d printing is both rapid and efficient, translating to speedier manufacturing with fewer errors. And this means it needs less human assistance which makes the entire system flow much easier. Already a pioneer in digital metal 3D printing, Pulesheng Technology is helping to redefine the concept of manufacturing metal products.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.