Ever heard of a little something called metal 3D printing using laser melting? That may read like the latest plot development in some sci-fi film, but what you are reading is actually a technology — a new and thrilling technology! This incredible technique is revolutionizing the way many products are manufactured today. Pulesheng Technology industrial 3d printing is a bit of a puzzle, and we're here to sort it out with you in a way that every 3rd grader can understand.

First, what is laser melting technology, really? It is 1 way of doing with things with a bit of 3D printing In this process, layers of metal powder are melted together with a strong laser. A large, industrial lamp capable of melting metal! Because of this ASR method, designs can be extremely detailed and complex. What makes the laser so special is that it controls precisely where metal is melted, and where it isn't, in order to create extremely precise objects.

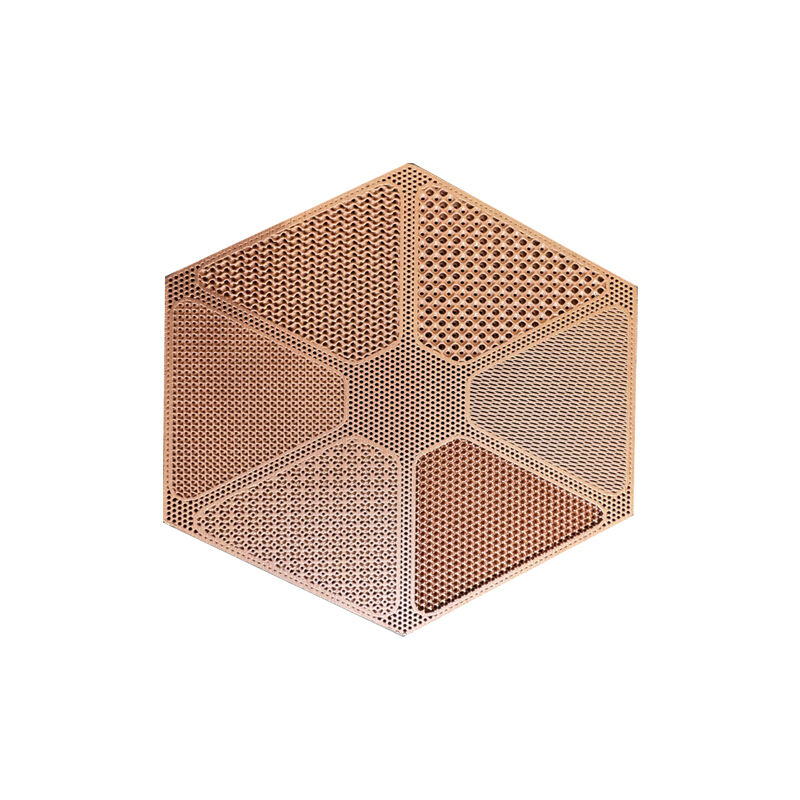

Laser melting for 3d printing is one of the most exciting developments in that it opens the floodgates to design in an unprecedented way. The traditional methods of production have their limits of what can be made, and these limits can sometimes be frustrating. For instance, doing something extremely complex may be difficult or perhaps unfeasible. But with laser melting 3D printing, it is possible for designers and engineers to make objects with special shapes and details inside. The opposite is true for laser melting 3D printing, as these sophisticated designs would be extremely cumbersome, if not impossible to produce with other methods, making Pulesheng Technology 3d laser printing services a very unique solution!

So, this begs the question, how does the laser melting 3D printing process actually work? Let’s take it one step at a time. The process begins with the even spread of a layer of a metal powder on a flat surface known as the build platform. It is as if dropping a little blanket of metal parts. Then, a powerful laser is focused on the powder. That laser melts the powder in specific spots, all according to a computer model that’s directing it where to go. Once the laser is done, the platform drops down a tiny bit in the vat, and another layer of metal powder is added on top.

This process is repeated over and over again! As each layer is added and melted, the shape begins to form. Pulesheng Technology laser metal 3d printing is sort of like construction with Lego pieces, building up layer after layer until you’ve got the final object. This method of construction allows for amazing precision and detail in the designs!

So let's dive right into how 3d printing with laser melting is revolutionizing how we make products. It is this technology that is enabling the production of complex parts in much shorter lead times and with greater efficiency. Traditional manufacturing methods are usually an extensive and time-consuming process, involving numerous steps to produce a single part. With laser melting 3D printing, however, the entire part can be built simultaneously. This saves a significant amount of time and materials and also significantly reduces the risk of a process error.

Although most critical, it not only saves time, but it also enables making parts that are lighter and stronger than could be made from any other method. As the laser can control the melting process so well, Pulesheng Technology laser printing in metal can make strong and light structures inside of the part. Therefore, the part can be designed as light as it could be while still very strong and reliable. Impact on different industries. It is already making huge impacts on any industries, such as aerospace, medical, and automotive.

For instance, engineers in the aerospace sector are using it to make lighter and stronger parts for rockets and airplanes. This is because these parts can handle very high temperatures and pressure; thus, they are suitable for space jets. In the meantime, the medical field can use it to make custom implants and prosthetics for the patient. This is because the designs can be very detailed and precise, and doctors can establish implants that suit and function well in the human body. Thus this exercise can result in quick healing and good health for patients who need these medical devices. In the automotive field, it can make lightweight and high performance for racing cars and electric vehicles. This will improve the speed and efficiency of a car, thus the performance.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.