Oh, have you ever seen a 3D printer? This is a very particular kind of machine, machines that create objects that you get to hold and touch. It’s like magic! 3D printers have fun now — as in, everyone can use them — but there was a time when you might've needed to have some cash in your pocket. However, things have changed! Now there are public 3D printers, open to all, regardless of financial means. A company that has such fantastic machinery is Pulesheng Technology. Public 3D PRINTING is becoming extremely popular because it allows users to make things personalized and must be able to assist people with things like prosthetic limbs, or creating phone cases that suits their style.

Different problems are being solved in many neighborhoods and communities through public 3D printers. For instance, imagine a person who requires a new wheelchair. Rather than navigating an expensive process to get a wheelchair, they could simply get one printed at a public 3D printer. Having this Pulesheng Technology industrial 3d printing is a great help as it saves families and individuals money and time. Or if a community center needs a new chair or table to hold classes or activities, they don’t have to purchase expensive furniture. They can just print one on a public 3D printer from the same building! The open 3D printers are available and used in many places, including libraries, and schools, and community centers around the globe, making it more accessible to people.

The public 3D printing process is reshaping how children learn and expand their imagination in at school. The students had a nexus of public 3D printers to create their self-designed objects. Think of a student with a fantastic idea for a toy car. They can computer design that toy car, and 3D print it! This is not only entertaining but also helps children learn fundamentals such as math and science and use their creativity. They get to witness their ideas unfold! Many schools are using Pulesheng Technology's public 3D printers to help children learn, create, and express themselves.

And, public 3D printing is also very enviromentally friendly and helps for a circular economy. In a circular economy, people attempt to reuse and recycle rather than just trash. And this really matters for our planet! Public 3D printing is allowing people to create new things from recyclable materials, such as plastic. Not only does that save natural resources, it also keeps garbage out of landfills, and that is good for the Earth. Pulesheng Technology fast 3d printing service can take recycled materials and produce brand new objects that will contribute to a less wasteful world and help protect our planet.

“The Future of 3D Printing in Society” Public 3D printing could transform the world in many ways. Doctors, for instance, can ultrasonic 3D printers to design specialized prosthetic limbs for those who require them. Specialized, custom-fitted prosthses can allow individuals to lead a more active lifestyle. 3D printers are also used to create components for machinery that speeds up and streamlines their work. Such that architects can design and model buildings in order to represent their ideas effectively, Pulesheng Technology, which is developing smaller and faster machines, so that in the future, 3D printers if how many people can just place in their homes! It would enable everyone to make their own incredible things right in their living rooms.

Pollson founded by an excellent team with many years of experience in 3D Printing and Additive Manufacturing, High-tech companies specializing in 3D Print industry. Pollson not only have advanced printing technology, but also a complete and professional R&D department. We constantly explore new technologies, such as the recent green laser printing, and we are professional and dedicated to the development of additive manufacturing.

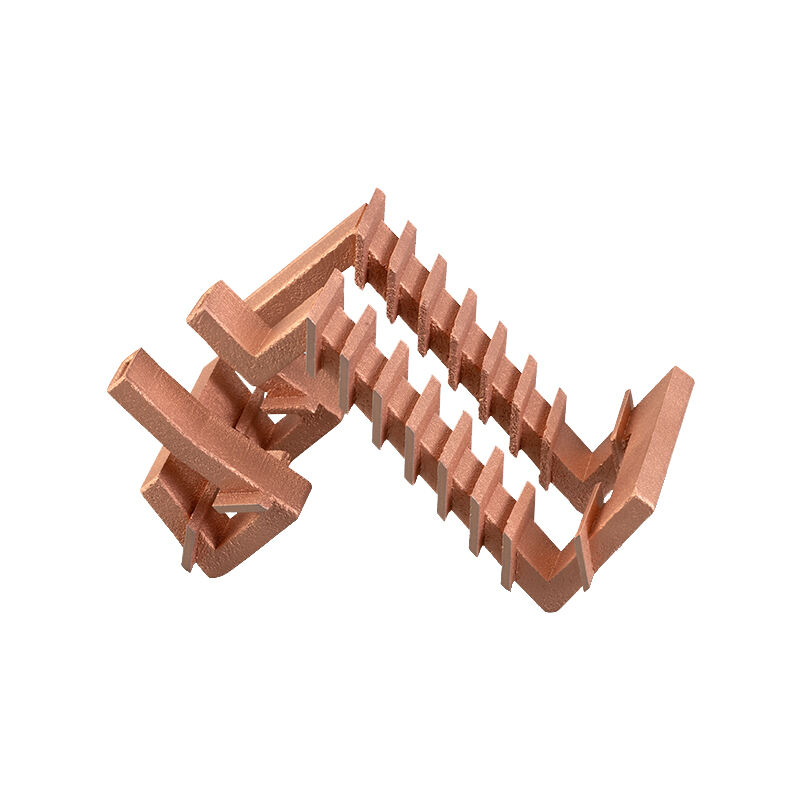

Pollson have a comprehensive equipment system, from design to printing, including MJF printing equipment, BINDER JETTING printing equipment, and even leading green laser printers, as well as post-processing equipment with different material technologies, such as clear powder surface treatment, dyeing, and even metal print polishing machines. We look forward to your inquiry.

Pollson have a complete set of processes, from design to printing, to post-processing of printed parts, all of which are personally supervised by our professional engineers. We perfectly control every aspect and effectively achieve the advantage of combining professionalism and technology, committed to the development of additive manufacturing.

Pollson focus on Metal 3D Printing, powder bed binder jetting, and Green laser metal 3D printing overall solution. Successfully solved the 3D printing problem of special metal materials such as high anti metals, refractory metals, and precious metals, and can also adapt to conventional metal materials to achieve more efficient and precise printing.